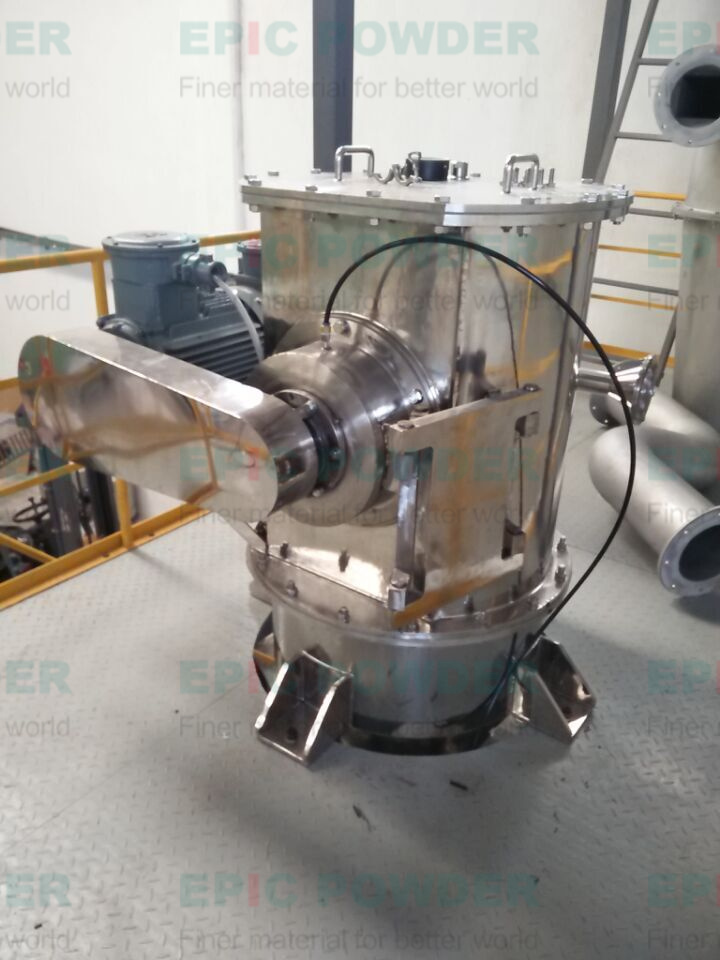

1800 Memblag green vulcanization promotion agent ultra -fine grinding equipment, Youmingke achieved synchronous engineering and lean production through ERP projects, and optimized management in production supply chain maintenance, financial resource allocation, and human resources deployment. Based on advanced barcode technology, the target management information system has been established. From procurement orders to product shipping, the barcodes are tracked throughout the process to effectively solve the problem of deposit and delivery management in the production process. Implement strict supplier management systems, strengthen supplier quality control awareness, and implement life cycle quality monitoring and accident tracking to products and suppliers. There are many types of mechanical pieces of Youmingke Fan Machinery Machinery, such as: MJW-L type, MJW-A, MJW-W, MJL-W, TSM soda-specific type, MJL-P needle disc type type Mechanical crusher, MZ vibration crusher, RTM vortex crusher, MJL-F hammer mechanical crusher, MRM-G series, MRM-C series and other different uses, different particle size, suitable for mechanical crushing of different materials crushing machine. There are also many application industries: battery materials, fine chemicals, metallurgical powder, medicine, non -metal mine, environmentally friendly desulfurization, high -tech materials, food/cosmetics/health products, building materials and solid waste. Here are a material introduction that we have already done experiments: Stalks are the general term for the part of the stems and leaves (ears) of mature crops. Usually refers to wheat, rice, corn, potato, rapeseed, cotton, sugarcane, and other crops (usually coarse grains). More than half of the products of crop lighting are existed in straw. Stalks are rich in nitrogen, phosphorus, potassium, calcium, magnesium, and organic matter. They are a multi -purpose biological resources. Stalks are also a kind of coarse feed. It is characterized by high crude fiber content (30%-40%), and contains lignin. Although lignin cellulose cannot be used by pigs and chickens, it can be absorbed and utilized by anti -animal cattle and sheep. 1800 meson green vulcanization promotion agent ultra -fine grinding equipment, Youmingke machinery equipment has sold more than 100 countries, customers are located at home and abroad. So far, more than 3,000 customers have cooperated. Several customers, randomly screen a display as a display for more customers to understand the strength and service capabilities of Youmingke. Cases of Yumingco's aluminum acid mechanical grinding machine: The company is a world -leading manufacturer of high -performance pouring materials for aluminum -mounted agents, with a history of nearly a century of production. All eight factories distributed worldwide are produced and operated in accordance with the ISO9002 standard. Excellent industrial production shows a series of products with high quality and high stability. The company is a leading enterprise in the industry. In the process of building a factory in the country, it has found that the domestic ultra -micro crushing equipment has tied similar foreign companies in terms of performance. In terms of price, it is more advantageous than similar imports from foreign countries. Finally, MJW410-L mechanical grinding crusher of our Shandong Youmingke Fan Machinery Machinery was used as productionequipment. Technical parameters of aluminum acid mechanical grinding crusher: finished granularity: D97: 20 \u0026 mu; M Production capacity: 100kg For powder production For enterprises, customized production and non -customized products are an advantage. The demand of each company is different. Therefore, the non -standard customization of powder equipment has been given. Our Shandong Youmingke powder machine is a non -standard company of powder equipment. Our customized aluminate mechanical grinding crusher for the customer is a good case. Corporates that are customized by powder equipment are welcome to contact us. The processing area of \u200b\u200bpink powder is clean, and the production area strictly controls the pollution of microorganisms to work objects, which meets the corresponding \u0026 ldquo; static \u0026 rdquo; Without metal pollution, the agency processing equipment uses different lining materials according to the needs of the material. From the incoming side to the discharge end of the discharge end, the increase in metal foreign matter is controlled to the PPM level. Standards for zero pollution of processing materials.