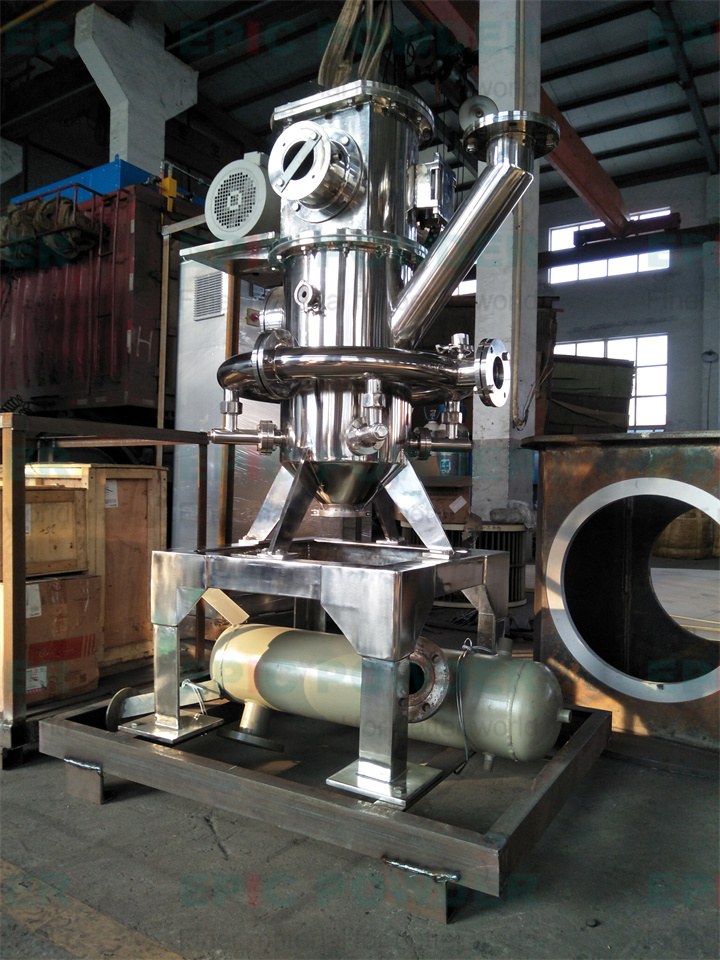

170 asbestos super fine grinding equipment. In the era of Internet+popularization, cross -border e -commerce has become a major direction for the transformation and upgrading of traditional manufacturing. Together with major e -commerce platforms, self -built enterprises B2B websites, weaving goes to the world's online sales network. Qingdao Youmingke Flutin Machinery produces a variety of powder engineering equipment. The mechanical crusher has a variety of categories and models. There are different equipment solutions for different particle size, different materials, different industries, and different applications. Below is selected from many ultra -micro -crushed materials to introduce: Graphite, also known as: Shi Ni, Shihei, Shi Lu, Shidai, thrush, charcoal, black lead. Carbon monoucture; chemical formula: C. There is no pure graphite in nature, which often contains impurities such as SIO2, Al2O3, Feo, CAO, P2O5, CUO. Graphite is generally iron and black; the single shape is mostly pointed, fine fiber -shaped, scales, a small amount of leaves, and the form of the collection is mostly powder, earthy, and crystal shape, and not light; semi -metallic luster, half metal luster, luster,, semi -metallic luster, half metallic luster, luster,, semi -metallic luster. The hidden crystals are dim; hardness is 1 ~ 2; the proportion is 2.21 ~ 2.26g/cm3; the melting point is 3652 ° C; the boiling point is 4827 ° C; Essence Graphite can be used to make refractory materials, conductive materials, wear -resistant lubricating materials, petrochemical, wet metallurgy, acid -base production, synthetic fiber, papermaking, etc.; Models and high -temperature metallurgical materials, atomic energy industry and defense industry, and electrodes. In addition, graphite is also the wear agent and rust -proof agent of glass and papermaking in light industry. It is an indispensable raw material for making pencils, ink, black paint, ink and artificial diamonds, and diamonds. From the founding to the present and foreign domestic and foreign customers, more than 3,000 customers have been cooperated at home and abroad. The following only introduces customers of the company's mechanical crushing machines. Materials can help many companies that need to know about relevant information. You Mingke adheres to the development of globalization and provides customers with high -quality products and services. 170 asbestos ultra -fine grinding equipment, Case of Youmingke Pigment Machinery Mechanical Fractoring Machine: This customer is a larger pigment chemical enterprise in Zibo, a blue pigment Professional manufacturers. 12,000 tons of copper 、 、, cobalt 酞 酞, and 酞 酞 年 are produced annually. During its production process, the color of the pigment is needed. Through the ultra-micro-crushing of the pigment, the quality of the product is improved. After a multi-party comparison of the same type of equipment, the MJW510-W mechanical grinding crusher of our MJW510-W machine is selected. Compared with the same type of equipment, our company's product is more reliability, the crushing particle size is more uniform, and the particle size after crushing is narrow, and there will be no large particle size range. Technical parameters of pigment mechanical grinding crushing machine: finished granularity: D90: 13\u0026 mu; M; Production capacity: 130kg/h For powder production enterprises, customized production and non -customized products are an advantage.The demand of each company is different.Therefore, the non -standard customization of powder equipment has been given. Our Shandong Youmingke powder machine is a non -standard company of powder equipment.The pigment mechanical grinding machine we customized for the customer is a good case.Corporates that are customized by powder equipment are welcome to contact us. The smooth landing of the customer EPC project is inseparable from the strength support of Youmingke: strong scientific research strength: cooperate with major universities and research institutes across the country, set up ultra -micro powder technology research institutes and area occupied areaThe 5000 square meters of test bases have achieved scientific and technological transformation and a number of patents of 23 industry -university -research projects.