The airflow ultra -micro crushing machine has improved greatly compared with the past few years. The improvement of its equipment structure and the improvement of crushing performance have made the airflow super crusher become an indispensable member of the crushing equipment, but Nonetheless, as a airflow ultra -micro crushing machine manufacturer, when receiving the crushing needs of different customers, there are still many disadvantages that the airflow ultra -micro crushing machine cannot be overcome. A large amount of R \u0026 D power, vigorously improved and optimized, can make it more adaptable to market trends.

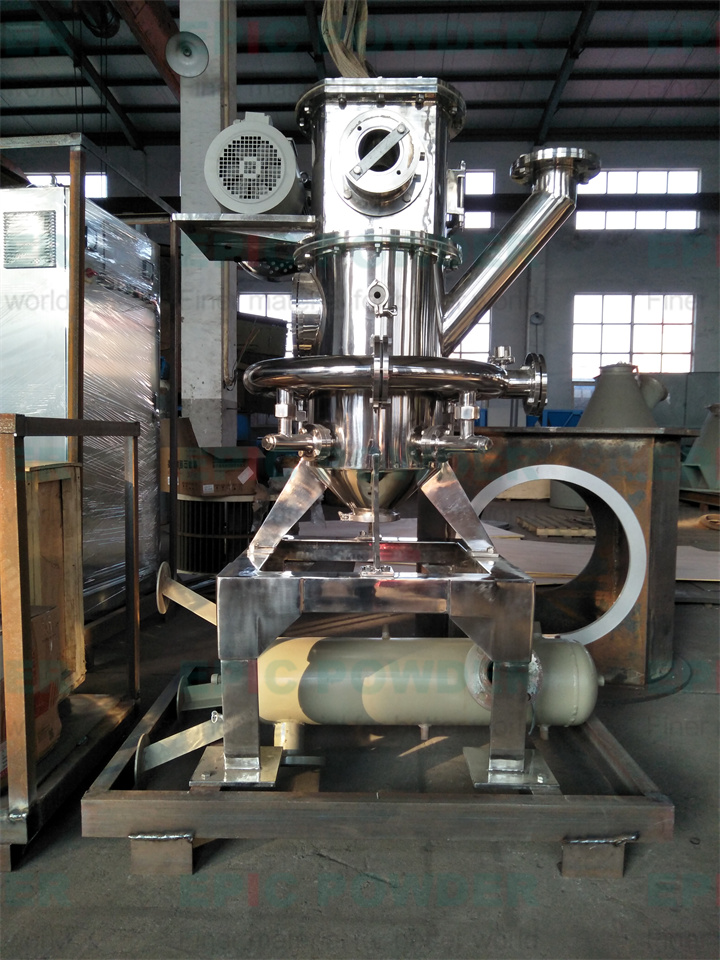

The airflow ultra -micro crushing machine, unlike other crusher, it is under the action of high -speed airflow, and Cutting and the impact, friction, cutting of materials and other components to crush the materials

It is understood that the air flow can be operated in a sterile state; the production process is continuous, the production capacity is large, the self -control and automation level are high. Essence However, the production cycle of mechanical impact crusher, vibration grinding, mixing grinding and other crushing equipment is often longer, which makes the production efficiency low; a large amount of heat produces when the material is crushed, resulting in the deterioration of thermal sensitivity materials; and the wear of the equipment will pollute the product products Essence Therefore, these mechanical fragments can no longer fully meet people's requirements for the increasingly higher and higher pink material materials. The airflow crushing equipment has a trend of replacing mechanical crusher in terms of production of ultra -fine powder.

In order to meet the higher requirements of the development of pink products, biotechnology and new material technology development, the research on the granularity, purity and particle size distribution of powder products should be improved. , Optimize the ultra -fine air flow crushing equipment, develop new equipment, and pay attention to the matching design of crushing and classified systems.

In addition, there are not many large equipment in my country. Among the above ultra -fine air -flow type ultra -micro crushing machines, comparison, fluidized bed airflow crushing machines have obvious advantages. Therefore The design of the guidance of crushing equipment; the biggest disadvantage of the airflow ultra -micro crushing machine is that the energy utilization rate is low, so it is necessary to seek ways to reduce energy consumption and increase energy utilization.