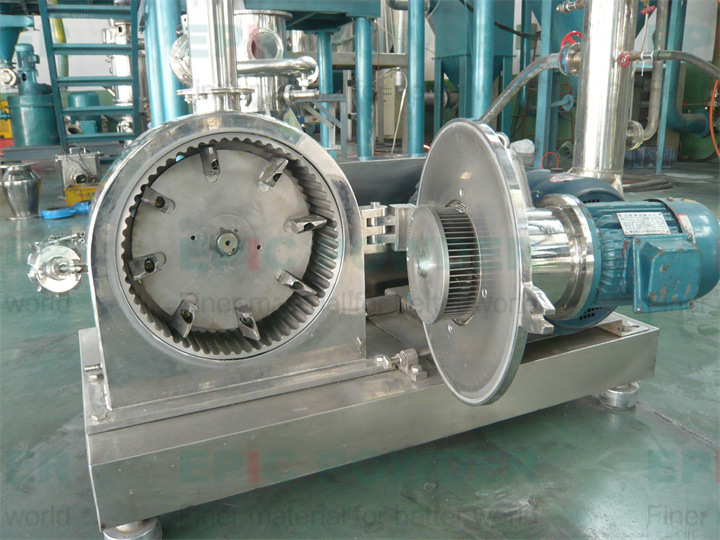

MJW hierarchical impact grinding (mechanical ultra -micro crushing machine) is one of the main products of Qingdao Youmingke Fan Machinery Machinery. For the unique crushing mechanism of this machine, it determines its wide range of applications, powerful and changeable features: It can be applied to plant fiber materials, can be suitable for plant shell materials, and can be applied to non -mineral light calcium and heavy calcium crushing. Compared with the traditional crusher, its fineness can be crushed to thinner.

The characteristics of the MJW hierarchical impact grinding (mechanical ultra -micro crushing machine):

1. The mechanical structure is compact and reasonable, small volume, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption, low energy consumption. High efficiency, stable rotation, low noise, reliable seal, no dust pollution, simple installation, easy disassembly and repair, convenient replacement parts

It is necessary to use a large air in the cavity or water jacket to cool down to reduce the crushing calories and prevent the disadvantages of the material particles sticking to the wall and the sticky disk surface. The flow of airflow in the machine can play a role in cooling, suitable for crushing processing of weak thermal substances such as coatings, food, and medicine (low softening points). Circular crushing can also be used with inert gas protection.

3. The crushing and grading machine can be distributed out in time when the material requirements are required to avoid crushing and the granularity distribution of the material is narrow.

4. A variety of materials suitable for processing industries. Without stopping, you can adjust the particle size arbitrarily. The product has a uniform grain size, and the fineness can reach 10-4um

5. The application of the machine is widely used. It is suitable for Mo's hardness less than 5 and the water content of less than 10%.

6. For the gatherings, there are very good dispersion and dispersing functions, with automatic residue discharge, not easy to crush the function

7. Using negative pressure operation can reduce the dust on the environment to the environment Pollution.8. It can run continuously and the process is short.

9. The cover is an open type, which is convenient for cleaning. When the crushing object is changed, it will not be polluted.