What are the differences between power batteries and energy storage batteries

The power battery pack is a whole, and each group of batteries must cooperate with each other. Nowadays, domestic diaphragm technology has made breakthroughs, and domestic products have obvious imports. At present, the most common electrolyte is used as electrolyte, which accounts for half of the cost of electrolyte. As the 21700 battery is widely used, the cost of power battery will further decline, and the energy density of the battery next year will reach another step. As a source of power for new energy vehicles, power batteries are the most important parts of the three -power system. We divide the lithium battery into power batteries and energy storage batteries. So what is the difference between them? How did the power battery produce?

Power batteries as the source of power for new energy vehicles, which are the three -electric system The most important part. We divide the lithium battery into power batteries and energy storage batteries. So what is the difference between them? How did power batteries produce?

Power battery and energy storage battery

Energy storage The battery is used as energy storage, and the power battery provides driver energy. In fact, each model of the battery will produce 4 versions, also known as high and low, the highest matching battery single section capacity is the largest, but considering the cost, the highest model is usually not used as a power battery. It only chooses to use the midfield as a medium match as a medium. Power battery, low -equipped for energy storage batteries.

In addition to the difference in battery capacity, power batteries have high requirements for consistency. There are many factors that affect the consistency of power battery, such as capacity, impedance, electrical characteristics, temperature characteristics, decaying speeds, etc. of the electrode. The above factors are inconsistent and will directly affect the difference in the output parameters during the operation.

The power battery pack is a whole, and the batteries of each group must cooperate with each other. Power batteries are the source of energy of the car. Before leaving the factory, it must be tested many high -temperature and high pressure tests to ensure the consistency of the battery. The energy storage battery obviously cannot do this.

Upstream: High -nickel becomes mainstream

The upstream of the upstream involves all raw materials for production batteries, including lithium, nickel, cobalt, manganese and graphite. liquid.

According to the ratio of nickel cobalt manganese materials, we can be divided into 532 batteries, 631 batteries, and 811 batteries. In order to reduce costs, high nickel batteries are mainstream.

In addition to lithium titanium titanate in the ternary material, the other ternary materials are black. And the so -called ternary materials are compounds, which are formed by mining, processing and smelting of various ore materials.

Negative materials are generally graphite, because graphite is high temperature resistance, conductivity, thermal conductivity, stable chemical properties, and good plasticity, so graphite is widely used in the production link of lithium batteries. In terms of processing technology, graphite has no burrs, and it is more tolerantEasy to polish and grind, the weight is lighter, which greatly improves the lightweight of the battery.

Midstream: In 2019, 21700 batteries will be widely popularized

Mid -reunion includes the production of polar ear, electrolyte, and battery cells. The most important of which is the production of battery cells.

The main function of the diaphragm and pole ears

The main function of the diaphragm is to separate the positive and negative poles of the battery to prevent the two poles from being short -circuited. In addition, the function of the electrolyte ion passes. The diaphragm is the highest technical barriers in the four key materials of lithium batteries, and it is also the material with the highest gross profit margin. Nowadays, domestic diaphragm technology has made breakthroughs, and domestic products have obvious imports.

The pole ear is the metal conductive body attracted from the positive and negative pole from the cell. In popular terms, the ears of the positive and negative battery are the contact point for charging and discharge. This contact point is not the copper piece of the battery we see, but a connection inside the battery.

The pole ear is divided into three materials. The positive electrode of the battery uses aluminum (al) material, the negative electrode uses nickel (Ni) material, and the negative electrode also has copper nickel (NI \u0026 mdash; CU) materials. They are all films and Metal with two parts of composite.

Electrolytic solution

The electrolytic solution acts as a medium of lithium ion flow between positive and negative poles, which has a pivotal effect on the operation and safety of lithium batteries. At present, the most common electrolyte is used as electrolyte, which accounts for half of the cost of electrolyte.

18650 battery and 21700 battery

18650 are the most widely used batteries, 18 represent the diameter, 65 representing length, and the last 0 represents cylindrical battery. However, the energy density of 18650 was limited. In order to increase the battery capacity, another model 21700 was derived, which was first applied to pure electric vehicles by Tesla.

After using 21700, the number of battery sections will definitely be greatly reduced, and the difficulty of system management will be reduced. At the same time The total cost is 24%, and the cost of battery packs is expected to decrease considerable, and the number of batteries will be reduced by 1/3.

downstream: Lightweight road is far away

downstream power battery PACK is produced. Under the current limited energy density, to increase the battery capacity, the battery must be pushed up. So The volume of power batteries will increase. At present, the lightweight of pure electric vehicles has been optimized, but the quality of the battery is still focused.

The car said that the new energy summary: Although the cost of the battery has dropped a lot, the power battery is still expensive in terms of the proportion of power battery prices. As the 21700 battery is widely used, the cost of power batteryIt will further decrease, and the energy density of the battery next year will reach another step.

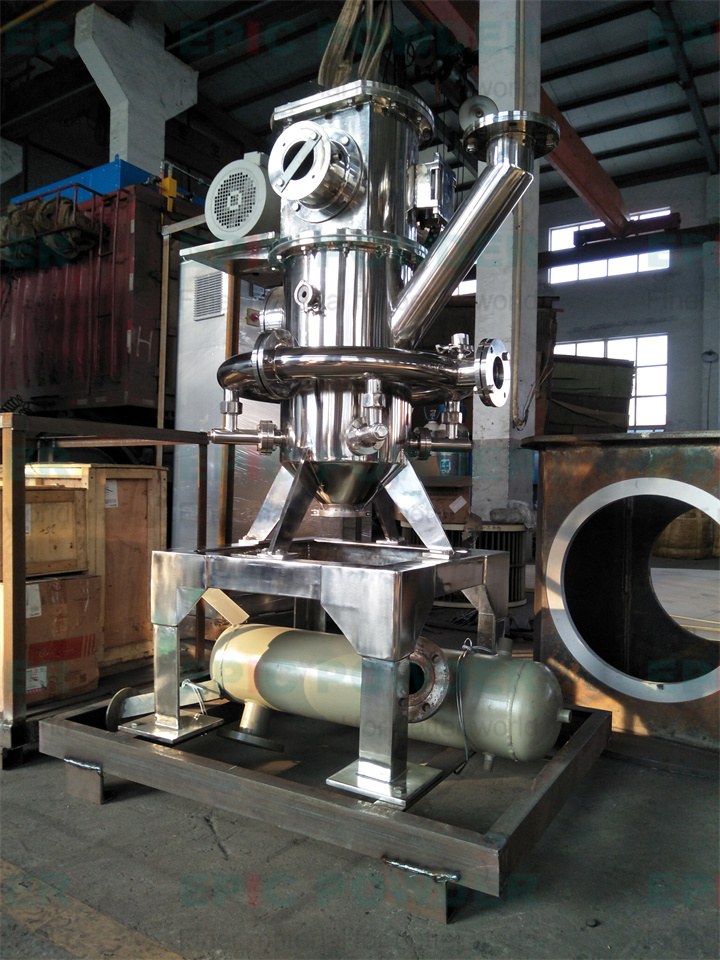

A Lithium Electric Materials Co., Ltd. in Chongqing, which is engaged in the R \u0026 D and production of lithium -ion battery positive materials (including positive materials for information electronics batteries, automotive power batteries and energy storage batteries, etc.) Sales. Two production lines have been completed and put into operation, with an annual production capacity of 2,400 tons. The lithium battery material crushing machines that need to be used in their production process are purchased from our company, and various accessories including production equipment are also provided by our company. You Mingke powder machinery provides not only equipment, but also high -quality after -sales service. Make a smooth operation of the equipment.

Shandong Youmingke Fan Machinery always firmly believes that the basis of global brand is the improvement of product and service quality, and behind the quality is a awe of the market. From online to offline, from single channels to multi -dimensional communication, from domestic to overseas, Shandong Youmingke Fan Machinery has always been carried with dealers. The brand of industrial powder equipment is the vision, and it has continued to strode forward and achieved new breakthroughs. In the field of industrial powder equipment, it has sent a strong \u0026 ldquo; Chinese voice \u0026 rdquo;