The critical speed at the temperature of the airflow crusher is 320m/s. If the temperature rises to 480 degrees, the kinetic energy also increases by 150%. Therefore, it can be very good to improve the work quality and temperature. It is beneficial to improve our crushing effect. Based on understanding the pressure of work quality is the main parameter of the air -spraying or airflow, and it is also the main parameter that affects the crushing fineness.

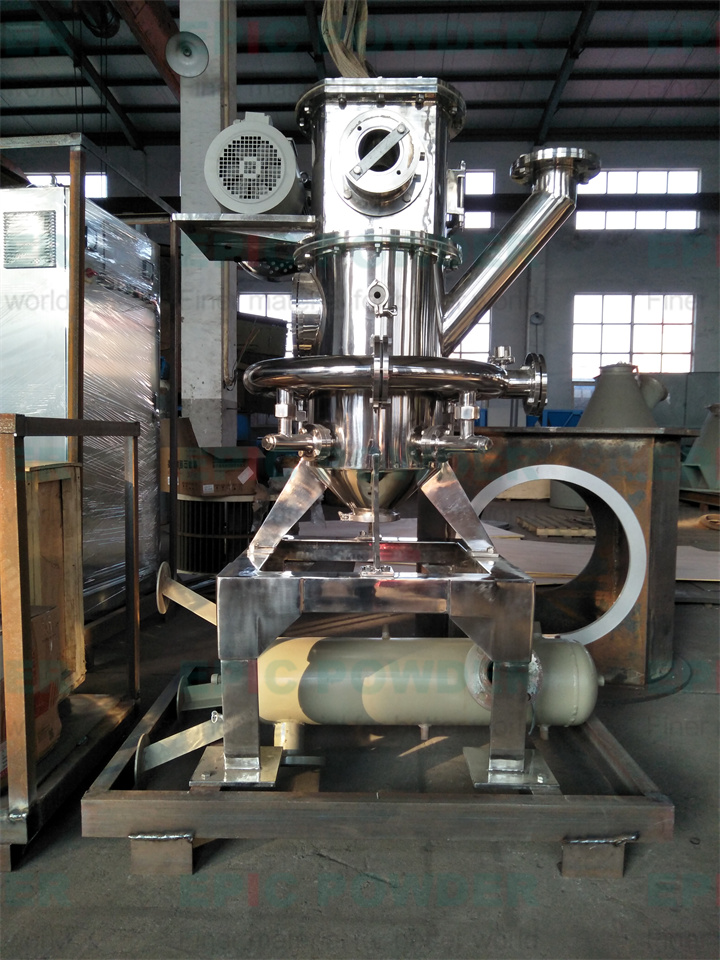

Dedicated airflow crushing machine for rare earth polishing powder, full negative pressure operation during processing, no dust pollution at the scene, ensuring the cleaning and drying of the environment. Graphite crushing grades are accurate and large, and the output is large! You can choose dedicated equipment according to different raw materials, fully automated control, and low energy consumption. Dedicated airflow classifier for rare earth polish powder, crushing grading accuracy is arbitrarily adjusted between D97 \u003d 3-74 microns. Penal appearance plastic surgery function, spherical graphite \u0026 ldquo; potato shape \u0026 rdquo;. Bag -type dust removal, division anti -blowing, offline ash clearing, the collection rate of more than 75%, effectively reducing the losses of raw materials.

While the pursuit of profits, Youmingke continued to pay attention to the stakeholders such as employees and other stakeholders, attaching importance to the career development and self -worthy realization of employees. The quality of work and life of employees reduces the anxiety, helplessness and resignation rate of employees, and helps employees solve their problems at various levels such as society, psychology, management and health.

Professional powder airflow crushing machine manufacturers, complete models, quality assurance, high -quality and low prices, good -selling nationwide, convenient operation, powder airflow crusher welcome new and old customers to consult!

The use of fixed asset gas flow crusher, the critical speed at the temperature of the airflow crusher is 320m/s. If the temperature rises to 480 degrees, the kinetic energy also increases by 150%. Quality and temperature are also very beneficial to improve our crushing effects. Based on the pressure of the pressure of work quality, the main parameters of the production of air injection or airflow are also the main parameters that affect the crushing fineness.

The service life of a fixed asset gas flow crusher. A mineral company in Hebei is a well -known mineral processing enterprise in Hebei. The company has always used a variety of dry dispersing equipment and has not achieved the ideal effect. With excellent performance, dry and dispersing processing equipment. After coming to the Youming Science Factory for inspection and experiment, I believe that You Mingke has rich experience in the field of drying and dispersing. Cost, it has now developed into Youmingke's high -quality customers.

In recent years, the attention of green environmental protection and sustainable development has mentioned unprecedented heights. Whether it is Ningde era or Youmingke powder machinery, it is constantly practicing the concept of sustainable development. There may still be infinite challenges in the future, but as a shoulderFor large -scale enterprises with social responsibility, Youmingke Fan Machinery will continue to adhere to technological innovation and work with partners to achieve a unified development of economic, environmental benefits and social benefits.