Silicon micro powder is crushed, ball mills (or vibration, airflow grinding), flotal, pure water, high pure water by natural quartz (SiO2) or melting quartz (natural quartz) Treatment of micro -powder processed such as processing and other processes. Silicon microfilling is a non -toxic, tasteless, pollution -free inorganic non -metal material. Because it has good temperature resistance, poor acid -alkali corrosion, poor thermal conductivity, high insulation, low expansion, stable chemical properties, high hardness and other excellent properties, it is widely used in chemical, electronics, integrated circuits (IC), electrical appliances, plastic plastics , Coatings, advanced paint, rubber, national defense and other fields. With the rapid development of high -tech fields, silicon microfream will also enter a new period of historical development.

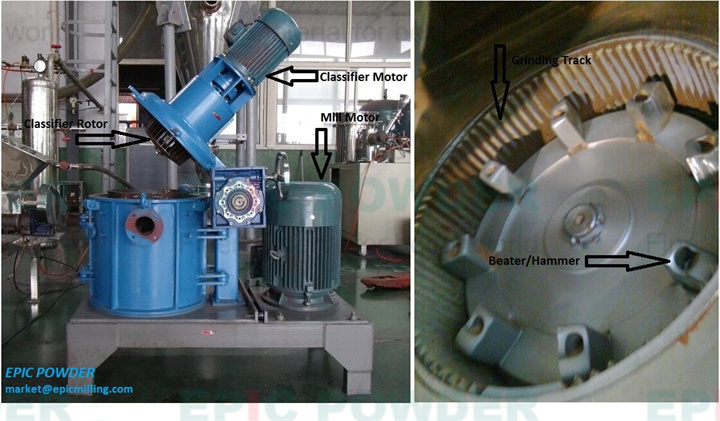

Super hard material air flow crusher, Youmingke Steel Slag crusher uses German technology, high-precision airflow crusher, and continuously innovative and upgraded technology. ; M. The nano -grade/sub -micron level that can be achieved in the dry method can effectively solve the problem of large air viscosity and product reunion. The granularity of the finished product is easy to adjust, less damaged parts, and good wear resistance. The advanced casting process is adopted, and the service life is long.

Youmingke provides systematic training for technical personnel sent by customers to better meet the project needs. During the practice of technical personnel, our training lecturers will continue to follow up the project operations to ensure the orderly development of the project and ensure that customers' production lines are continuously stable and efficient. The rich training course expert lecturer followed up throughout the process. Multi -dimensional training course settings, lecturers follow -up mechanism throughout the process, no matter what the foundation you are, you can easily master the operating skills.

The airflow crusher applied in my country's industrial industry mainly has several types: flat airflow grinding, fluidized bed -to -spray air grinding, circulating tube air grinding, spray -type air grinding, target airflow, target airflow, target airflow grind. According to the design structure, the airflow crusher can be roughly divided into: fluidized bed airflow crusher (including vertical and horizontal type), and discs sprayed. Compared with the impact grinding, the airflow crusher has a wider range of applications and smaller size. It is especially suitable for the crushing of high -value materials, high -value materials, and high value -added materials. Therefore, the price of air flow crusher is relatively high in mechanical crushing. The price of equipment is mainly due to the material characteristics and industry requirements of grinding.

Silicon micro powder is crushed, ball mill (or vibration, airflow grinding), floating, pickled, pickled, pickled, pickled Micro -powder silicon microfim powder processed by multiple processes such as pure water treatment is a non -toxic, odorless, non -polluting inorganic non -metallic material. Excellent performance such as expansion, stable chemical performance, and high hardness are widely used in chemical, electronics, integrated circuits (IC), electrical, plastic, coatings, advanced paint, rubber, national defense and other fields.With the rapid development, silicon micro -powder will also enter a new period of historical development, super -hard material air flow crusher.

A chemical company in Jiangsu is a well -known listed company in Jiangsu. It is a manufacturer of toothpaste -grade calcium phosphate for the United States. When expanding production capacity, it is agreed that You Mingke can achieve product fineness and production capacity in terms of product fineness and production capacity. The performance of imported equipment abroad determines the purchase of Youming science equipment. This device is a large airflow crusher used by the chemical industry, with an gas consumption of 160 cubic cubic/minute.

Youmingke Fan Machinery has always adhered to its original intention, helped all walks of life to increase the governance of ecological environment, accelerate the pace of industrial adjustment and upgrading, promote the continuous improvement of air quality, and strive to achieve a high -quality driving development future. Sports machinery will adhere to the concept of \u0026 ldquo; high starting point design, high -quality development \u0026 rdquo; to make a positive sense of responsibility and mission for social and economic development and ecological civilization construction, laying a stable foundation for the social environment and the healthy and sustainable development of the enterprise. It provides a solid guarantee for the further realization of economic benefits, environmental benefits, and social benefits.