Environmental protection is a topic that the country has always attached great importance to it. Environmental protection has made many companies stop or even stop business. In recent years, the rapid development of air flow crushing machines are not only well used in the pharmaceutical industry, but also widely used in various industries. So is environmental protection issues in daily applications pass?

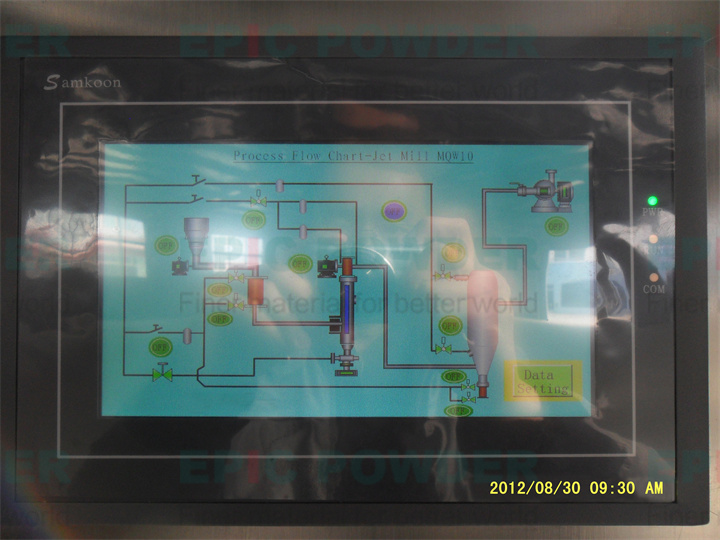

First of all, let's take a look at the principle of the principle of the airflow crusher series equipment: the working principle of the airflow crusher of the airflow is: the airflow crusher and the cyclone separator, the whirlwind separator, The dust collector and the winding unit form a standard crushing system. After filtering and drying the air, it is sprayed into the crushing cavity at a high speed through the Laval nozzle. The crushed materials follow the upper air flow to the hierarchical zone under the effect of the fan. Under the powerful centrifugal force generated by the high -speed rotation of the rotating turbine, the thick and thin materials are separated, and the fine particles that meet the particle size requirements enter the cyclone separator through a hierarchical wheel. Collect with the dust collector, the thick particles dropped to the crushing area and continued to crush. Secondly, let's look at the functional characteristics of the airflow shredder 1. After the material is crushed by the airflow crusher, the product is good, the granularity is narrow, and the particle size is adjusted, and the range is between D97-150. 2. The airflow crusher can shatter the various materials of Mo's hardness, which can achieve dry method crushing. 3. Suitable for crushing of materials with high hardness, high purity and high value. 4. The airflow crusher can perform low temperature without medium crushing, suitable for the crushing of thermal, low melting points, sugar -containing and volatile materials. 5. After crushing the material, the product purity is high after crushing, and the airflow crusher mainly depends on the impact between the materials. It is different from mechanical crushing, so the equipment is wear -resistant and the product purity is high. 6. It can be used in series with multi -level class machines, and products that can produce multiple granular sections at a time. 7. The crushing process of the airflow crusher is in a closed crushing, and the dust is relatively small. Low noise. The production process is clean and environmentally friendly, which fully meets the environmental protection standards. 8. The inner wall of the airflow crusher is smooth and there is no dead ends, and it is simple to remove and clean. During the whole crushing process, the airflow crusher is in a full confidential state. There is almost no dust generation in the production process. There is no pollution in the operation workshop, no dust, which fully meets national environmental protection standards. Qingdao Youming Ke Fan Machinery Professional R \u0026 D production airflow crushing machine, as well as various types of Chinese medicine crusher, is relatively favorable, and the equipment functions are comprehensive. Welcome everyone to come to our company at any time.