Mesing is a very important link in the process of pharmaceutical production (PRODUCE). In recent years, with the continuous development of my country's pharmaceutical industry, the crushing machinery industry has developed rapidly, but traditional crushing machinery has gradually gradually gradually gradually used Exposure of some shortcomings. There are several types of flat airflow crusher, fluidized bed to spray air crusher, circulating tube air crusher, spray air crusher, and target airflow crusher. Among these types of air flow crusher, the application of flat airflow crusher, fluidized bed to spray air crusher, and circulating pipe airflow crusher are widely used. There are certain limitations in the granularity, powder output, powder collection, and preservation of effective ingredients. In this environment, the airflow crusher technology will provide new ways to the ultra -fine Chinese medicine powder with better development efficacy and better variety.

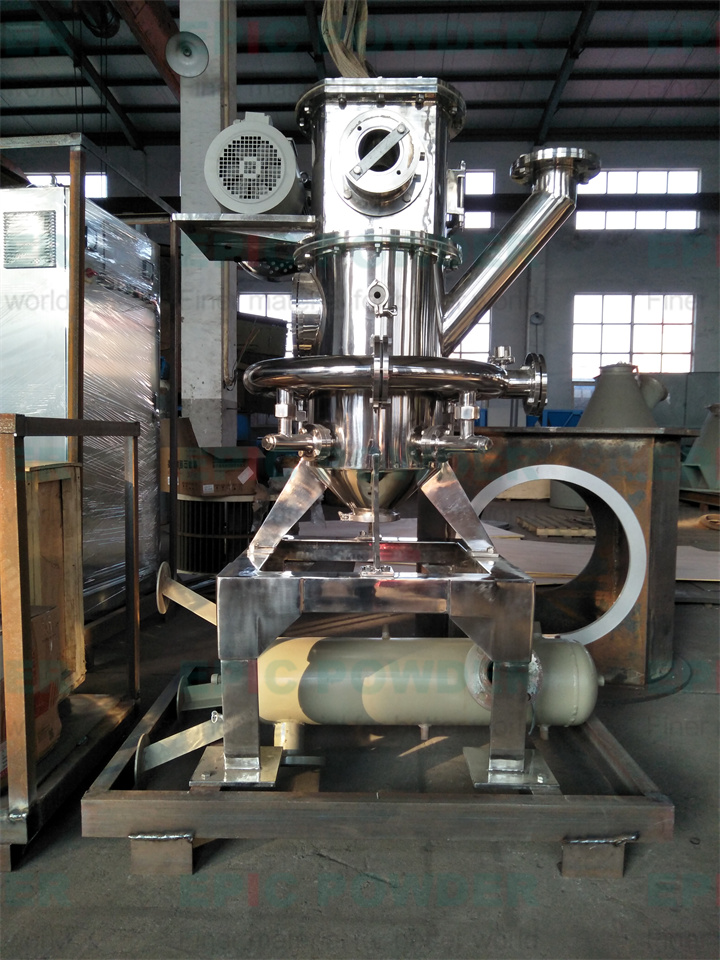

When the gas is used to spray the raw material, the raw material is crushed into the crushed room, and there are multiple crushed nozzles outside the crushing room, and the spray supersonic airflow is sprayed. Make the material from high -speed impact of the air flow and collide with each other, friction and crushing, and the hierarchical tube separates the thick particles, and the thick particle cycle returns the crushing room to continue crushing. Outlets can be distributed uniformly (jūn y \u0026 uacute; n) ultra -fine powder. After using the airflow crusher for a long time, we need to clean it. Cleaning the airflow crusher to disassemble it. The specific disassembly skills (SKILL) are as follows: 1. Cleans: Close the total power supply of the device, and then use the brush to remove the remaining dust (form: solid particles) in the machine. Clean layer by layer. Under the negative pressure airflow driven by the airflow crusher, the turbine grading device set by the top is driven by the top -level. The fine powder is forced to pass the classification device, and the cyclone collector and the bag dust collector are captured. The centrifugal force is thrown to the wall and sinks back and returns to the crushing cavity to continue crushing. 2. Removal of the feed bucket: First, remove the four bolts on the base (composition: head and screw composition), and then remove the grouped bucket. 3. Remove the screen: open the air flow crushing machine door, and then remove the screen. 4. Remove the active gear: first loosen the tight nut, and then separate the activity gear from the host axis. After that, remove the activity gear and place it safely. 5. Remove the fixed gear: Remove the screw (scream), and then remove the fixed gear. When disassembling the airflow crusher, you should be careful to avoid damaging the parts or body by excessive motion. By changing the ordinary air from the gas source into an inert gas such as nitrogen, carbon dioxide gas, etc., the aircraft can make this machine a inert gas protection equipment. It is suitable for crushing and grading of flammable and explosive, oxidation and other materials.