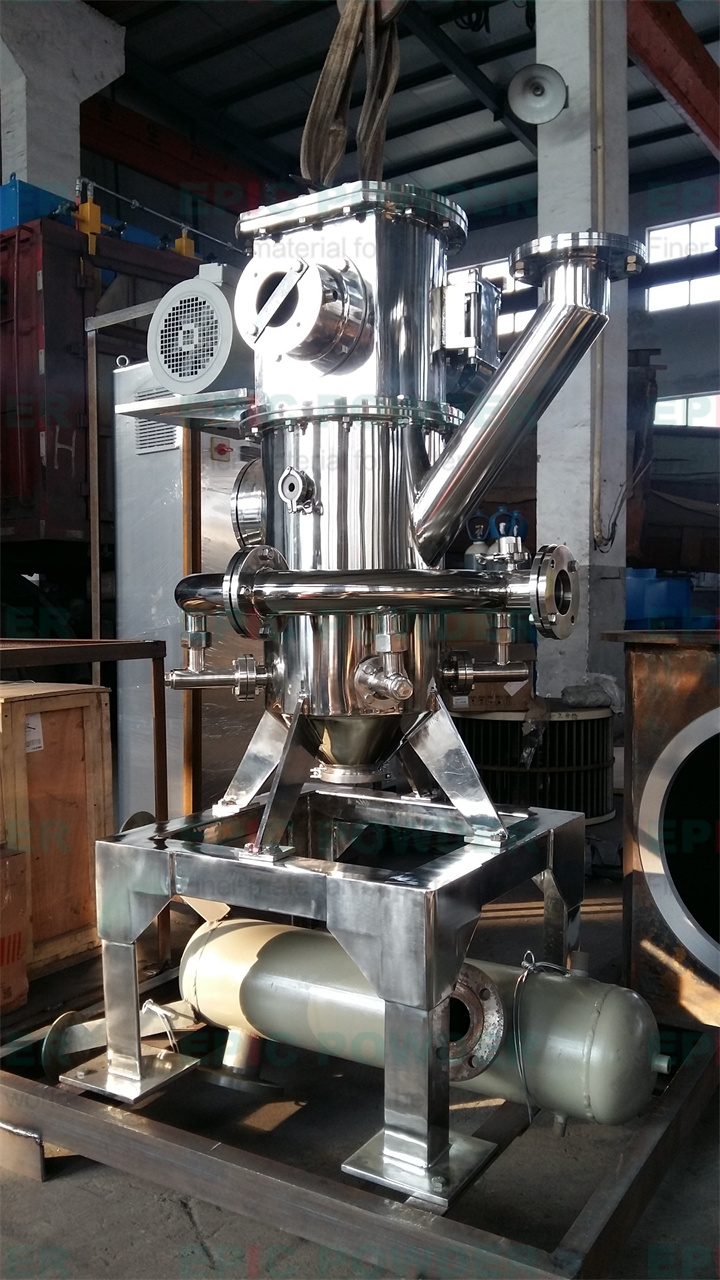

Among the existing airflow crushing machine technology, powder that is separated to crushing granularity is generally a hierarchical wheel. Because the hierarchical wheel is set in the crusher barrel, the crusher barrel is full of high -pressure gases. Therefore The sealing between them has always been difficult to solve. Under normal circumstances, between the hierarchical wheels and bearing support seats of the airflow crusher are combined with a dynamic sealing ring and a quiet sealing ring to achieve the effect of sealing and turning the spindle. However, due to the high pressure of gas in the body barrel, many powder will enter the bearing below along the gap between the static seal under the action of pressure, which will cause the bearing to be blocked and cannot work, and the main axis cannot rotate again.

The material moves to the hierarchical zone under the action of the fans, and under the powerful rotation of the high -speed rotating turbine, so that Separation of thick and thin materials, fine particles that meet the requirements of particle size enters the cyclone separator and dust collector through a hierarchical wheel, and the thick particles drop to the crushing area to continue to crush. The motor drives the hierarchical wheel to rotate at a high speed in the hierarchical shell (the speed can be adjusted arbitrarily), forming a strong centrifugal force in the classifier. The gas powder mixture entered the classifier first enters the interior of the hierarchical wheel. Under the action of centrifugal force, the large or heavy particles are sold directly by the centrifugal force. Affected by the centrifugal force, it naturally falls to the crushing host to continue crushing or falling to the material port for collection; small or light materials are small or light -hearted, and hovering inside the hierarchical wheels. At the same time, the pipeline moves to the next component to be classified or collected. The speed of the hierarchical machine can be adjusted by adjusting the speed of the hierarchical wheel, and the purpose of dividing the specified granular material can be achieved. Adjustment of the hierarchical wheel speed of the air flow crusher: In the case of other parameters, increase the speed of the hierarchical wheel and increase the fineness of the product; otherwise the product's fineness increases. There are accurate granular cutting points for the grade wheel. According to the different requirements of the granularity of the product, the speed of the classifier can be selected within a certain range. The hierarchical wheel motor working current adjustment of the airflow crusher: The current of the hierarchical wheels changes with the amount of materials in the hierarchical cavity (assuming other conditions remain unchanged). There are many materials in the cavity, large current, low grading efficiency, and increased output; opposite efficiency increases, and production decreases.