Medical raw materials need to be produced into various preparations after super detailed processing. The smaller the particle size of the raw material, the more thorough the release of the drug. Medicine raw materials are generally scattered into water or in solvents (such as Kabham solution), which is made of drug suspension to obtain medicines for medicine. The raw material is super fine -grained. It is a high -tech equipment. Let ’s take a look at the processing methods and characteristics of the medical airflow crusher with the editor.

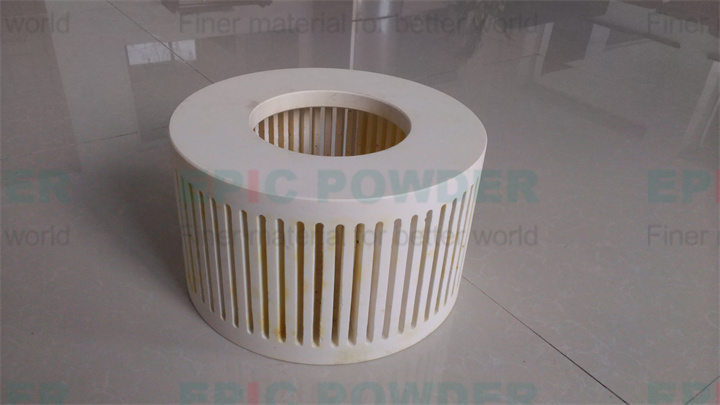

When the pharmaceutical airflow crusher runs, the pharmaceutical powder material enters the flat cylindrical under the direction of compressing air or nitrogen from the direction of the line. In the air flow crushing box, under the action of the surrounding airflow nozzle, it is continuously added, and a spiral -shaped motion trajectory is formed. When the slower material that just enters the smashed box is accelerated on the spiral movement trajectory, it will be accelerated, and it will be Cracks to achieve the crushing effect. The role of centrifugal force will allow larger particles to move around the crushed box, while smaller particles are discharged from the middle of the crusher. Features of pharmaceutical air flow crushing machines: 1. Strong crushing ability, low energy consumption, and relatively small product relatively thinner. 2. The high wind pressure generated during the large crushing space and the turbine can not only improve the production capacity, reduce the crushing phenomenon, and effectively avoid the deposition and blockage of the sieve network during the crushing process. 3. Because the shearing is strengthened, the crushing ability of fibrous materials is higher than that of ordinary equipment. The pharmaceutical airflow crusher is suitable for small batch production in the laboratory. The structure is simple, sturdy, stable, and has good crushing effect. The crushing can be directly discharged by the host grinding cavity. Made for stainless steel. The processing of the internal machine of the shell reaches the smooth surface, changing the phenomenon of rough and accumulating powder in the inner wall of the machine, making the production of medicines, food, chemical industry more comply with national standards.