\u0026 emsp; \u0026 emsp; as one of the dust -free airflow classifiers as one of the powder processing equipment, you can see that it is a kind of equipment that prevents dust and pollution, which is the environmental protection policy that the country has vigorously implemented today. It is consistent, so in recent years, the dust -free airflow classifiers have been more favored by many processing enterprises.

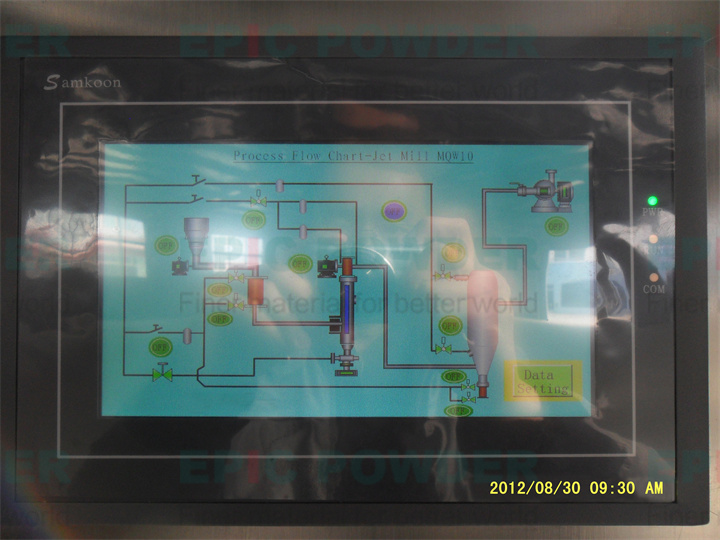

\u0026 emsp; \u0026 emsp; rotor impeller of the dust -free airflow classifier is a composite two -way centrifugal type, the leaf wheels are high -speed, and a negative voltage is constituted in the lower part of the impeller. In the district, the atmosphere in the hierarchical cylinder enters the air inlet of the lower part of the impeller, and is excluded from the entrance along the upper lobe. The radial fine -granular ring flows out. Under the influence of the control ring, the airflow is twisted upward. The airflow via the upper part of the plate to move inward, enter the lower impeller through the upper entrance of the impeller, excludes from the lower impeller entrance, and the excluding airflow twists and moves in the tube. Reincarnation activity constitutes a one -time reincarnation. The material output from the star -shaped material valve fell into a high -speed twisting dump, and threw it towards the material blocking ring under the influence of the centripetal force. Under the influence of the material barrier, the material was sprinkled down in the hierarchical cylinder. Under the influence of interspersed airflow, the thick particle material slides in the coarse material collector from the wall of the control ring, while the fine powder is transported to the microfim pink whirlwind collector below (the inner tube of the hierarchical cylinder in the middle of the rotor. ), Such as the material, the material is divided into two parts: thick and thin, while the remaining atmosphere is inhaled from the central part of the middle of the rotor, flowing through the leaves, radiation fine -grained ring, and controlling ring, and then from the surrounding area of \u200b\u200bthe rotor to the middle of the rotor Flowing back, constituting a continuous active reincarnation of cycling. The excess atmosphere that follows the material and the excess gas due to the high grading room temperature is high, and the excess of the atmosphere is crowded by the surplus air outlet to pipe the charged indoor airflow balance and stable. The Yufengkou set is filtering a bag to make the exclude atmosphere not pollute the environment. \u0026emsp;\u0026emsp;无尘气流分级机广泛应用于化工、矿物(尤其适合碳酸钙、高岭土、石英、滑石、云母等非矿产品分级)、冶金、磨料、陶瓷、耐火材料、医药、农药、食品、 Health products, new materials and other industries. \u0026 emsp; \u0026 emsp; all technologies of powder are a new cross -industry discipline, which is the product of modern high -tech development. There are many ways to prepare powder. The physical or chemical method is used to condense it to the size of the super particles at the level of atoms, departure, and molecular levels; the other is to use mechanical methods to crush the block of the block to the size range of the ultra -fine powder. Among them, the crushing method has attracted the attention of various countries due to its low cost and can adapt to large -scale industrialized production. It has become one of the most commonly used methods in the preparation of the pink system. In order to obtain the ideal powder, it is difficult to make the material meet the required granularity requirements at a time, and the product is often in a larger particle size distribution range. In the use of various industries, it is often required to be in a certain granularitydistribution range. In addition, in the process of crushing, there are often only some products in the powder that meet the particle size requirements, while the other parts do not meet the particle size requirements. If the product is crushed together, it will cause energy waste and the crushing problems of some products. The dust -free airflow grading machines must be solved through classification for these two problems during the crushing process. The grading of materials is one of the most basic operation processes in powder engineering. The particle size of the product is within a certain range, thereby ensuring the quality of the product and increasing its added value. The second is to cooperate with the powder grinding operation to form a circular powder grinding system, and to separate the qualified powder from the product in time, which can effectively avoid the occurrence of powder grinding phenomena, improve the efficiency of powder milling, and reduce product energy consumption. It can also easily control the fineness of the product to adapt to changes in product and process conditions. This is the reason why researchers have recently attached great importance to the in -depth research on the hierarchical theory and industrial experiments of the dust -free airflow classifier. It is precisely because of these two aspects that grading technology has been widely used in environmental protection, building materials, metallurgy, fuel, ceramics, food and other industries: the research and development and development of equipment for graded technology, and also received deep scientific research institutes, factories and mines Enterprise attention. The development of any device must be guided by theory, so the grading mechanism is of guiding significance for the design and manufacturing of the hierarchical equipment, and strengthening the development and application of basic theoretical research on the development and application of powder technology. Only by clarifying the hierarchical mechanism of the dust -free airflow class machine can we improve the vortex air classifier, and can design and develop high -efficiency and energy -saving classifiers for production, improve product quality, save energy, improve production efficiency, and reduce production costs. \u0026 emsp; \u0026 emsp; dust -free airflow grading machine is one of the main products of Qingdao Youming Science and Technology. Its grading accuracy and equipment process are among the best in the country in China, especially in the field of metal powder and alloy powder. Gas protection airflow classifiers have a very high shareholding, which has been unanimously recognized by users.