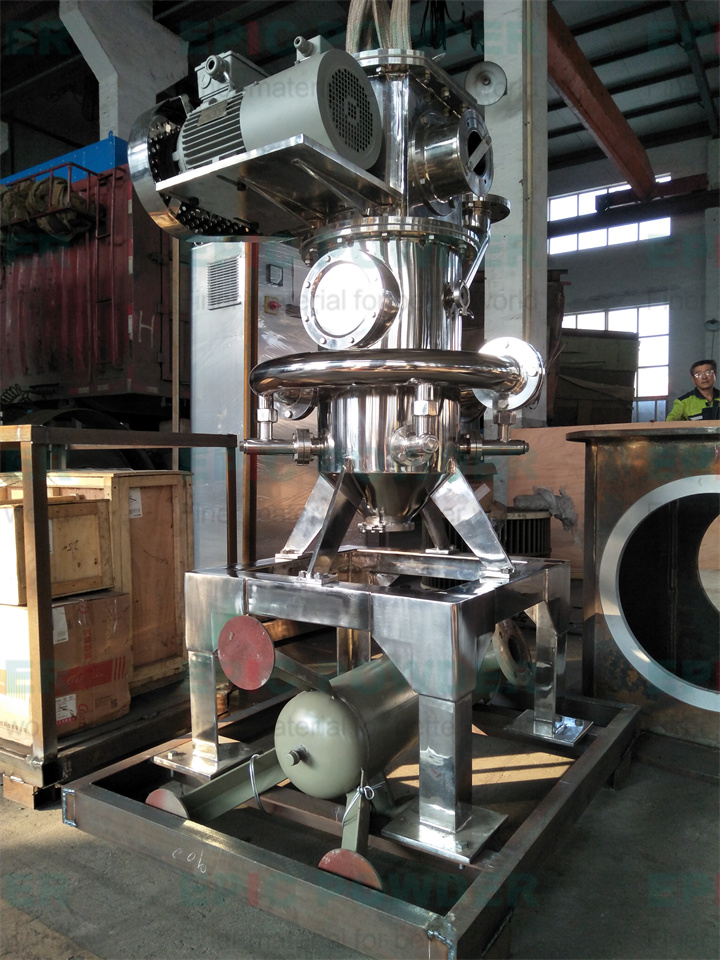

Ultra-fine air flow crusher is very common in today's chemical industry. It is usually used to crush solid substances to 3-74 microns. What way does the ultra-fine air flow crusher use to achieve substances? Today, we will focus on the working principle of the ultra -fine airflow crusher. Super fineization is a term used to describe dimensions, and the particle size is less than 10 microns. Ultra -fine gas crushing machines are used for hyperhide chemicals, drugs, pigments, minerals, and other substance solids, such as thermal sensitivity, corrosive and grinding materials. In many cases, the process of hyperhimage is usually considered as black boxes that produce fine powder and coarse particles. The super fine gas crusher runs in the compressed air, gas or high -pressure overheating steam. There is no active component of the ultra -fine gas crushing machine, so it eliminates pollution caused by contact with external grinding media. It is also an ideal process for grinding thermal sensitivity and waxing materials, because it does not produce a heat. Ultra -fine gas crusher is used for fluid energy. Take pancake spiral super fine air flow crusher as an example. Super fineization and classification are performed in the shallow cylindrical chamber. High -pressure air or steam is injected into the room by the specially designed nozzle placed on the Zhoubi. The axis of each shot is smaller, and the circumstances of the concerted concentric circle are cut. During the operation, the material enters the eddy current along the project and accelerates. The strong speed gradient near the shot causes the suspended particles of the material to collide with each other and reduce itself through wear and collision. Decreased size is the result of the high -speed collision between the granules of the process material itself. Does not involve grinding media. The air flow is discharged from the top of the top chamber, and the granification particles are inhaled into the cyclone separator collection system together. The heavier particles are maintained in the grinding room through the centrifugal force until it is super fine to the required size. The granularity of the feed is the key, restricted by the size of the gas flow device. For the 200-300 mm rolling machine, the maximum service size can be 1.5 mm. For smaller size rolling machines, the size of the feed is more fine. There are several factors, including operation and physical factors. They affect the fineness of the final product, such as feeding rate, nozzle size, nozzle pressure, nozzle angle, airflow rate, feed particle size, cavity diameter and width, and product export diameter. All these variables can be adjusted during operation, but it is more likely that once it starts, it only needs to change the feed rate to meet the required particle size distribution. In fact, the spiral air grinding process is not only controlled by the airflow crusher itself. This is a process involving different machines and components, which requires correct integration and control. These accessories include fluid energy, feeder, whirlwind separator, dust collector, etc. The demand for drug materials, including fine grinding active substances and germings, is growing. The injection of drugs and dried powder inhale requires a particle size distribution within 2-20 microns. It has a steep distributed curve and the smallest fine and large size particles. Air flow grinding is a very effective technology that is used to reduce the particle size of inhalation and other drug products. Among them,The size of the particles is associated with effective delivery. The advantages of ultra -fine gas crushing machines are not as easy to clean components for mechanical motion components to obtain very fine particles of particle size, and do not produce the disadvantages of the calorie ultra -fine gas crusher is relatively low in productivity. Typical materials Agricultural chemicals: bromylcesence, polymorrholite, metalis, bactericides, herbicides, sterilizers, etc.化学品:己二酸,钛酸钡,氯化钙,氧化铬,催化剂等陶瓷:氢氧化铝,碳化硅,铁氧体,玻璃,氧化锆等矿物:铝土矿,石膏,石墨,云母, Talge, Tentalum ore. Coatings: charcoal black, fluorescent pigments, titanium dioxide and other medicines: amino acids, antibiotics, aspirin, birdylactamic acid, sarcin, penicillin, vitamin compounds, etc. The working principle of the super fine gas crusher is the above. At present, in China, it is Qingdao Youmingke, which is relatively mature to produce ultra -fine air flow crusher. In this industry, it has more than 20 years of technological accumulation and production experience. There are more than 20 groups that integrate R \u0026 D, production and sales.