Shandong Youmingke Powder Machinery lasted for two years, and successfully completed the dedicated ceramic formation wheel with a diameter of 600. Can be used with airflow classifiers. Compared with ceramic horizontal hierarchical wheels;, a series of problems such as battery material adhesion, incompetence, and inaccurate grading were successfully solved. During the operation of the lithium battery orthopedic material of the lithium batteries of Qingdao Youming Scientific Research, the iron content of the iron content can be strictly controlled during operation.

; development concepts, adhering to quality first, service -oriented; , Continuously improve the efficiency and safety of airflow crusher, and are committed to providing customers with more secure, energy -saving and environmentally friendly air flow crusher products, creating more value for customers, creating greater benefits for employees, doing their best to society, more for society Large responsibility.

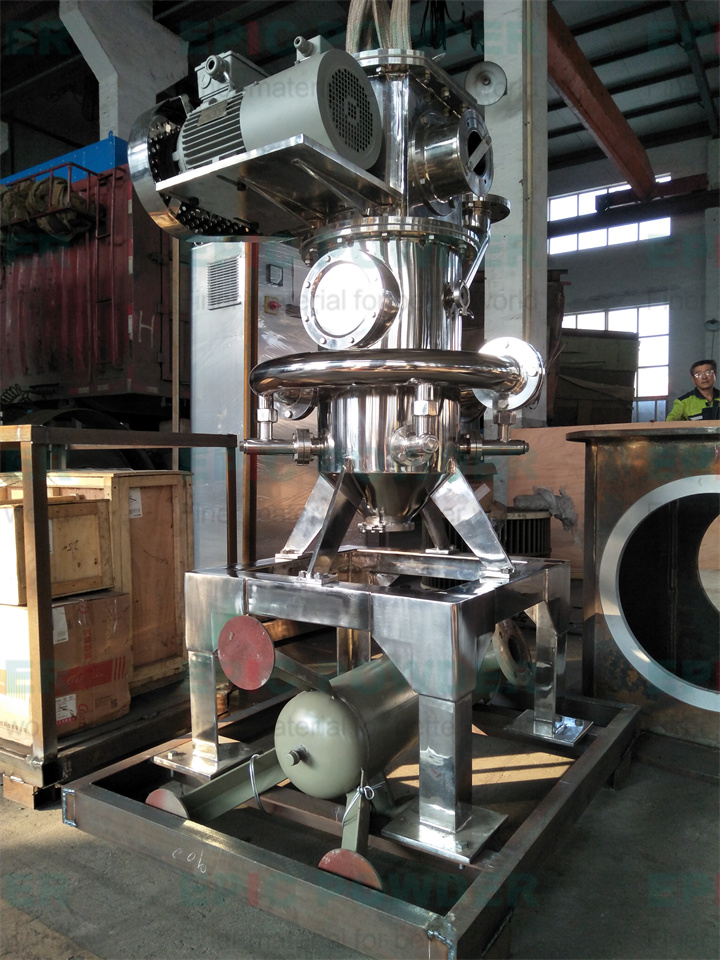

The crushing grading of the airflow lining in the inner protective ceramics has the following performance advantages: it is suitable for the dry method of various materials below Mo's hardness 9, especially suitable for the crushing of high hardness, high purity and high value -added materials. The breakthrough of granular acceleration technology has greatly improved the crushing efficiency, reduced energy consumption, too small, good granules, narrow granular distribution and no large particles. During the crushing process, the temperature of the air flow was reduced due to the sharp expansion of the airflow, especially suitable for the crushing of thermal, low melting points and volatile materials. The material collisions are crushed with each other, which is different from the crushing of the impact on the material such as the mechanical crushing by the blade or the hammer head. In addition, the comprehensive ceramic lining, so the equipment wear is small and the product purity is high.

Flow Character Equipment has the following characteristics: 1. The full use of high -efficiency high jet energy has greatly improved the crushing efficiency. 2. wear small fluidized bed+vertical turbine classifier; can process ultra -micro powder in high purity, narrow and width, avoid spray+vertical classifiers; Grade machine; wear out of the grading part. Under the same material, the service life of the device is equivalent to 20 times that of similar international products. 3. Highly stable and complete grading streaming fields and special sealing measures to reliably prevent the leakage of coarse particles. The vertical turbine hierarchical machine and the fluidized bed form an internal cycle, ensuring the qualified product particle size d97 \u003d 2 ~ 74 μm.4. The unique grading flow field is overly crushed, reducing the gas concentration of the hierarchical zone and avoiding crushing. 5. The variable combined structure can be used in one machine, which can be used as a crushing classifier and a separate classifier. 6. Full closed negative pressure operation, no dust pollution. 7. Easy to operate and repair, fast disassembly, and small noise.

科 Battery material air grading case:

A new material company is a new material high -tech enterprise specializing in the research and development, production and sales of lithium ion battery positive materials. There are many types of invention patents. The main products are lithium cobaltate, ternary materials and lithium manganate, and maintain a good cooperative relationship with many customers at home and abroad. A complete industrial chain of the positive electrode material of lithium -ion batteries is formed to provide customers with high -quality products.

Lithium carbonate is the basic material to produce two lithium salts and metal lithium products, so it has become the largest lithium product in the lithium industry. Other lithium products are downstream products with lithium carbonate. The production process of lithium carbonate can be divided into salt lake brine extraction and ore extraction depending on the source of raw materials. At present, foreign countries mainly use salt lake brine extraction processes to produce lithium carbonate, while my country mainly uses solid ore extraction processes. Lithium battery -grade lithium carbonate is mainly used to prepare lithium -ion batteries such as lithium cobaltate, lithium manganate, ternary material and lithium iron phosphate. High -pure lithium carbonate is mainly used in preparation of high -end lithium -ion battery positive materials and battery -grade lithium fluoride; in terms of photoelectric information, high pure -grade lithium carbonate is used to prepare lithium crichdate and lithium crickets; Lithium is also used in optical special glass, magnetic material industry and supercapacitors, pharmaceutical industries, etc. Youmingke is a well -known domestic ultra -fine powder solution provider. The company is located in the Chengnan Industrial Park of Jimo City, Qingdao City, Shandong Province. It has more than 50,000 square meters of mechanical production bases and a modern management system. The modification and the system integration of powder engineering equipment have provided solutions. In the past three years, the annual output value has exceeded 200 million yuan. You Mingke provides customers with installation and guidance services. After the equipment enters the venue, the service engineer will go to the site to guide the installation and provide the system training technicians to the client operator. The preface is carried out to ensure the stable and efficient operation of the production line, and the principles of the equipment equipment of the battery material vortex air gas grinding grinding machine. The principle of equipment equipment of the battery material vortex air gas grinding grinding machine