Traditional Chinese medicinal materials for ultra -fine processing through the gas flow crusher, not only have the characteristics of processing non -pollution, maintaining the original chemical properties of the material, and good powder shape, etc., and can make Chinese medicine materials have unique small size effects, surface or interface effects, etc. , So that it shows many excellent performance; when the drug is crushed to 10 μm to 1 μm, the drug will have new advantages such as accurate, easy absorption, specificity, and targeted. Can fully play the role of drugs, improve efficacy, and reduce the economic burden of patients.

from the problem consultation to the design of the plan, Youmingke provides customers with the most professional answer and the most comprehensive solution, and assist customers to formulate construction plans to provide customers with the most professional nanny level; private customization services. You Mingke has served more than 3,000 customers at home and abroad, and sold in more than 100 countries and regions in Asia, Africa, Europe, the United States and Oceania. Wide praise.

Ceramic internal lining air -flow crushing classifier application field: pesticide material: polymorphic spirit, methyl betotobadin, herbicide powder, insecticide powder, sterilizer powder wettable powder, etc. Medicine: Green Tea, Salva, Pearl Powder, Tuin Powder, Sanqi, West Green Fruit, Nimo Horizon, Non -Nobel, ibuprofen, Nitrate, Penicillin, pollen, pearl powder, Nimo Di are equally equal. Essence Food materials: barley flour, food calcium, coral reef, barley seedlings, glue sugar powder, etc. Pigment materials: iron oxide, chromium oxide, cyanop, cadmium red, cadmium blue, etc.

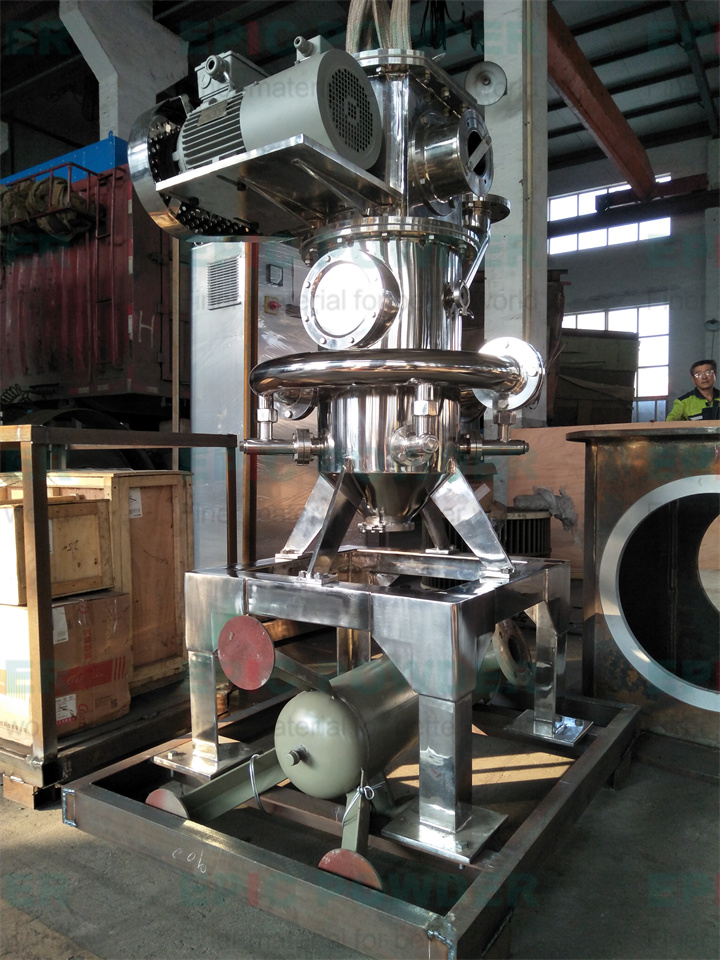

disk airflow also known as Spiral Jet Mill, which is mainly composed of feeding system, intake system, crushing-grading, and discharge system. Our company's disk -type airflow has a larger cavity with a cavity with a normal airflow. The enlarged cavity can be fed as much as possible in the grinding area. The ring and the upper and lower lids are fastened by the C-shaped quickly unloading the chip, forming a space for the crushing-grading room. Compressed air or overheating steam or other inert gases enter the gas distribution pipe from the feed jet port. Under its own pressure, the gas has a high -speed jet flowing from several nozzles around the seat around the circle. The feed sprayer consisting of the bucket, the feeding nozzle and the Wensuri tube is used as the feed device. The materials in the material in the fight are shot into the Wenqiuli tube by the spraying of the nozzle. After the material and the air flow are mixed with the airflow in the Wenqiuli tube, the crushed materials are brought to the center group and passed by the airflow to the central group tube. The axis of the group pipe enters the central exhaust pipe up or down the collection device.

科: The company is an industrial company, which integrates high -tech industries that integrate mineral resources to explore, collect, and deeply process them. There are six major categories of products: long stone powder, silicon micr powder, aluminum, aluminum Alum soil, kaolin and other products. The product has high whiteness, fine particle size, reasonable particle size distribution, and stable quality. It is widely used in industries such as electronics, electronics, silicon rubber, ceramics, and precision casting. The products are exported to many countries and regions in my country. The company needs to divide the airflow of ultra -long stone powder. In the end, our vertical air grades can meet customer needs. Product granularity: D50: 16.7

Food additive can be chemically synthesized, or naturally existing substances. Only after safety evaluation, it will not cause harm to people's health, and it is necessary to use in the process of processing in foods. Material can be used as food additives. Powder is processed on behalf of the powder. Youmingke is a company dedicated to providing customers with comprehensive and high -quality services. It has the world's advanced ultra -micro powder processing equipment, which can be widely used in ultra -microfanter processing of various materials. You Mingke's testing equipment is perfect, the service is in place, and in addition to the small and medium -sized processing of product development, our laboratory also provides the world's advanced product analysis technology and strict product control management system. Battery material air -flow grading machine manufacturer direct sales, Youmingke provides customers with installation guidance services. After the equipment enters the market, the service engineer will go to the site to guide the installation and provide system training for the customer operator. During the practical operation of the technical personnel, the training lecturer will continue to follow up the operation projects to ensure the orderly development of the project and ensure the stable and efficient operation of the production line. Direct sales of battery material air air flow grading machine manufacturers