An inert gas protection airflow crushing classifier (nitrogen protection powder equipment) is used in metal powder, prone oxidation raw materials, flammable and explosive raw materials, pharmaceutical ultra -microcomes, and other industries and raw materials that need to be protected by inert gas. The typical materials of inert gas protection airflow crushing classifiers (nitrogen protection powder equipment) include: micro -fine spherical aluminum powder, selenium powder, cymbal iron powder, cobalt powder, tungsten powder, magnesium powder, nickel powder, pink powder, etc.

The new ultra -fine powder material has become the upstream and original materials of most industrial manufacturing, and almost the production and manufacturing department of all the weight industries is almost scratched. In today's world, the production process and application level of ultra -fine powder has become a measuring symbol of the development level of national science and technology. Among the equipment that prepare ultra -fine powder materials, the airflow crusher of the fluidized bed laboratory has become the leader in the dry processing equipment. Essence

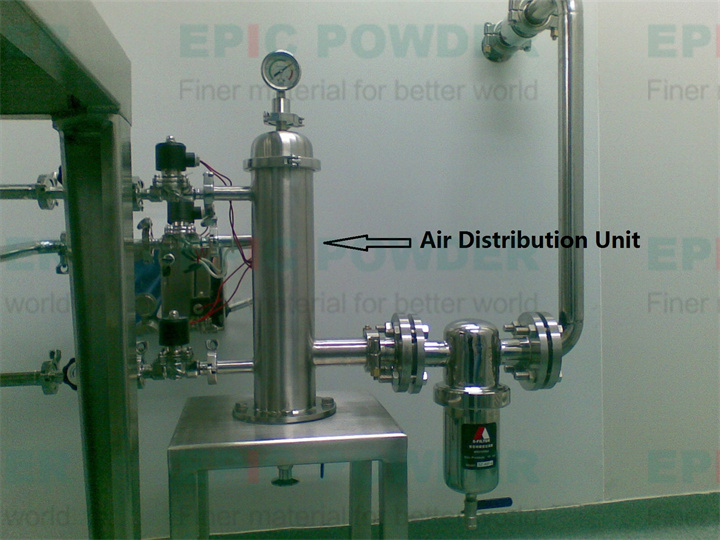

The airflow crusher of the fluidized bed laboratory is to compress the air through the freezing, filtering, and drying, and to form a supersonic airflow into the crushing room by the nozzle, so that Accelerated materials converge at the jet air flow of several nozzles, which produces severe collisions, frictions, cutting to achieve the super fine crushing of particles. However In the laboratory air flow crusher, the work intensity, high labor cost, and prone to miscellaneous objects into the fluidized bed crushing room. Production efficiency. The new -type high -efficiency fluidized bed laboratory airflow crusher produced by Qingdao Youmingke has the advantages of high -efficiency feeding, which solves the feed method of the traditional laboratory air flow fragments. , Conveyor plate, filter board, sealing cover, power pump, discharge tube, disbumed valve, first material tube, second material tube and storage box, can be manually raised manually and dumped into the laboratory into the laboratory In the air flow crusher, it can automatically put on the material, reduce the intensity of work, reduce the cost of personnel, and will not have impurities to enter the crushing room, eliminate hidden safety hazards, and greatly improve production efficiency.

ingenuity should not be just a business gimmick, but to maintain a awe, use the ultimate seriousness and perseverance to create the ultimate product. You Mingke Fan Machinery raised the service to the brand height through unremitting efforts, and established a marketing strategy with \"customer satisfaction\" and \"market -first\" as its main goal. Through the innovation and change of marketing services, the \"customer satisfaction\" focused on Value service creates value for customers and continuously improves customer satisfaction.