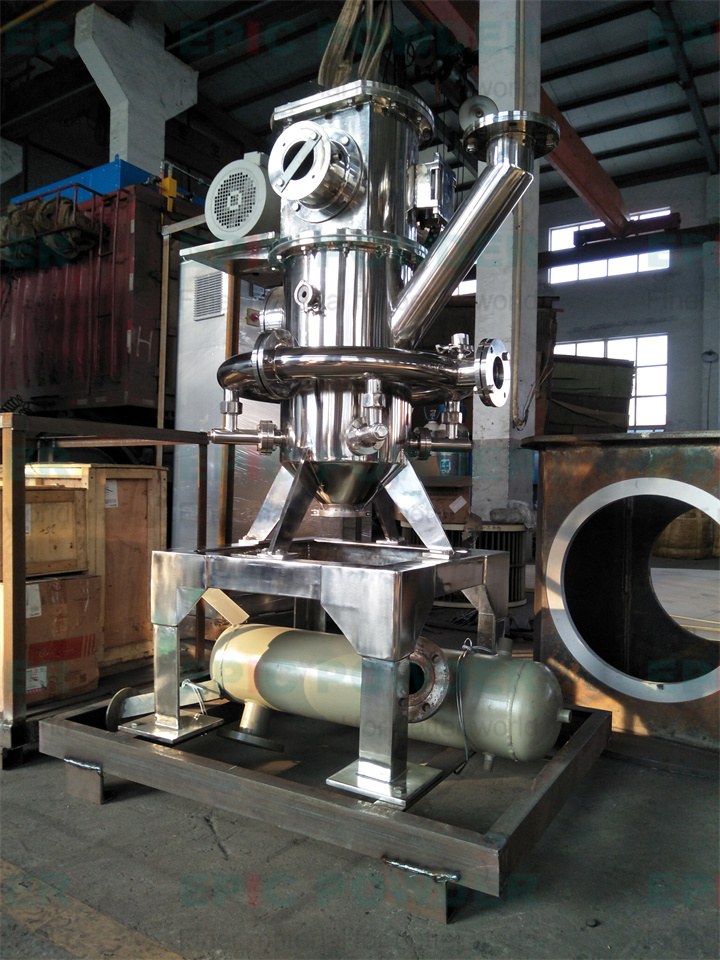

You Mingke Pink Machinery adheres to the new customer service concept of \u0026 ldquo; fingers, fully automatic \u0026 rdquo; from the user's needs and users' application status, greatly improving the safety performance of the machine, saving customers artificially artificially artificial artificially It has reduced the design concept of advanced production costs, superb manufacturing craftsmanship, perfect quality system, and meticulous service attitude! It is Yumingke adhering to \u0026 ldquo; Youmingke Fan Fan Machinery \u0026 RDQUO; This brand ’s eternal promise and thinking on each user, 170 me aluminum -acid microfilling equipment. Qingdao Youmingke Flutin Machinery produces a variety of powder engineering equipment. The mechanical crusher has a variety of categories and models. There are different equipment solutions for different particle size, different materials, different industries, and different applications. Below is selected from many ultra -micro -crushed materials to introduce: Paraffin is a mixture of hydrocarbons, so it does not have strict melting points like purified compounds. The melting point of the so -called paraffin refers to cooling the melting paraffin sample under the specified conditions, when the temperature of the stagnation period appears on the cooling curve for the first time on the cooling curve. Various wax products have good temperature resistance on paraffin, that is, non -melting or softening deformation at a specific temperature. According to the conditions of use conditions, areas and seasons, and the environmental environment, the commodity paraffin is required to have a series of different melting points. As a submarine heat storage material, paraffin has the advantages of phase heat storage material, with small changes in the process of fixing a liquid phase change process, good thermal stability, no over -cold phenomenon, and low price. And the development of aviation, aerospace, microelectronics and optoelectronics technology often requires a large amount of heat dissipation generated during high -power components to work in a limited heat dissipation area and extremely short time. The melting point phase change material can quickly achieve the melting point, and make full use of the submarine heat to achieve temperature control. The advantages of the relatively short thermal response time are widely used in high -tech systems such as aviation, aerospace, microelectronics, and energy saving of houses. From the founding to the present and foreign domestic and foreign customers, more than 3,000 customers have been cooperated at home and abroad. The following only introduces customers of the company's mechanical crushing machines. Materials can help many companies that need to know about relevant information. You Mingke adheres to the development of globalization and provides customers with high -quality products and services. Case of Youming Ke Crystal Sulfur Mechanical Members: A Chemical Material Trading Co., Ltd. in Shenyang needs a device crystal sulfur that can be used for crystal sulfur The explosion-proof system of the equipment has extremely high requirements after various investigations. Our company's nitrogen protection type MJW760-L mechanical impact crusher meets the company's production demand nitrogen explosion-proof mechanical impact pieces. There are advantages in consumption and other aspects Technical parameters: finished granularity: 200-300 mesh Production capacity: 1.5T Equipment principle: The efficient impact of inert gas protection is based on the normal efficient impact grinding and vertical turbine high -precision grading machine, by changing the airflow ingredients and changing the inlet air pipeline of the equipment to improve the equipment of the equipment to improve the equipment of the equipment The sealing process and other methods, the entire system for the design and development of material design such as flammable and explosive, oxidation and other materials is used as an inert gas as a fluid working medium. The full set of equipment is a full set of equipment. , Establishing turbine classifier, reference fan, closed replacement discharge valve, anti -severity pulse reflector eliminating dust collector, inert gas supplement device, etc., the exit of the fans is connected to the efficient impact of grinding into the air inlet, forming an inert gas confinement cycle System, 170 me aluminate microfilling grinding equipment. Professional installation and debugging to ensure smooth acceptance: Youmingke installation engineers will guide the equipment installation and debugging throughout the process until the trial operation of the entire production line is successfully met. Installation preparation phase: look at the components required for confirmation of ordering orders and counting equipment, and measure the elevation, geometric size and other measurement according to the drawings; the equipment installation stage: conduct on -site installation and planning according to the design drawing, gradually start installing equipment and related supporting facilities; Phase: Further check the equipment and perform debugging and maintenance before use to ensure that the operating characteristics of the equipment meet the needs of production; Equipment acceptance stage: Youmingke is responsible for training relevant personnel. Qualified letters.