The critical speed at the temperature of the air flow crusher is 320m/s. If the temperature rises to 480 degrees, the kinetic energy also increases by 150%. Therefore Our crushing effect. Based on understanding the pressure of work quality is the main parameter of the air -spraying or airflow, and it is also the main parameter that affects the crushing fineness.

You Mingke 7*24 hours of customer service hotline and 150+ service engineer standby at any time. Any problems in the production line can be complained to feedback. Youmingke will give a technical consultation reply within 30 minutes. Provide clear solutions within the hour, and provide services at the fault on the 3rd (10th).

Based on the physical characteristics of the positive and negative materials of the battery powder, different devices are used for crushing classification to achieve the best output ratio. According to a large number of successful cases of many companies in our company and battery powder, we choose our company's battery powder special mechanical ultra -micro crushing machine \u0026 mdash; classified impact grinding (effectively reduce the energy consumption of production equipment) to achieve the crushing effect; for lithium battery The specific material of nickel -metal hydride battery can be crushed with a fluidized bed air flow crusher. High purity requirements, anti -oxidation can use inert gas to protect crushing classifiers, isolate oxygen closed production.

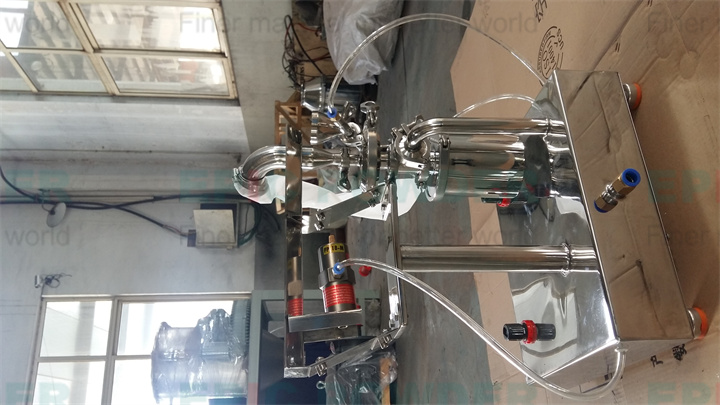

Consistence consists of a crusher, a whirlwind separator, a pulse dust box and a fan. This machine uses the relative movement between the tooth plate and the fixed tooth plate, so that the crushed materials are crushed through the impact of the tooth, friction, and materials of the materials. The device, then the fans are produced, the dust enters the pulse dust box, and is adjusted through the filter tube and recycling. The whole machine is designed according to the GMP standard, all made of stainless steel materials, and there is no dust in the production process.

科: This customer is a Steel Slag Application Technology Co., Ltd., which is mainly engaged in the reuse of steel residue. During its production process, the steel residue ultra -microfana needs to be sorted to screen out the required steel slag micro powder. The customer inspected many domestic powder equipment manufacturers, and finally chose the vertical air classifier of our Youmingke powder machinery machinery machinery Essence Steel residue air hierarchical machine parameter product particle size: D97: 5-75 μm H hour: 200-500kg For steel residue grading equipment, customers and friends are concerned about the factory quotation. As a large company manufacturing company, Qingdao Youmingke has always worked hard to provide customers with greater value. The fineness, production capacity, and installation venue of each project are important information for customized selection. Pre -sale service links, Youmingke has 24 hours online online. Customer service will always answer questions for you, provide the ideal hierarchical machine production line solution, and provide factory quotations based on this to escort the steel slag solid waste project.

Lithium carbonate grinding powder grading model, white charcoal black is the general term for white powder X-ray non-fordless siliconic acid and silicate products, mainly refers to the sedimentation silicon dioxide, gas phase silicon dioxide and ultra-fine dioxide dioxide Silicon gels also include powder -like synthetic silicate and silicate. White charcoal black is used in color rubber products to strengthen charcoal black to strengthen the needs of white or translucent products.白炭黑同时具有超强的粘附力、抗撕裂及耐热抗老化性能,所以在黑色橡胶制品中亦可替代部分炭黑,以获得高质量的橡胶制品,如越野轮胎、工程轮胎、 The noon tire and so on.

The quality assurance goal of Youmingke is to pursue the zero defects of all the super -microfanten equipment that are issued by the factory, actively implement the quality management of Liuxigma, and continuously improve the process control management capabilities through advanced data statistical analysis to create products that make customers satisfied with. and service. You Mingke provides customers with installation and guidance services. After the equipment enters the site, the service engineer will go to the site to guide the installation and provide systematic training for the customer operator. During the practical operation of the technical personnel, the training lecturer will continue to follow up the operation projects to ensure the orderly development of the project and ensure the stable and efficient operation of the production line. Lithium carbonate grinding powder hierarchical model