Geeky for excellence and win with quality! In order to ensure \u0026 ldquo; zero defects, continuously improved \u0026 rdquo; Quality improvement in various tasks is solid and effective. The actual operation status has initially formed an organic combination, a comprehensive and effective quality control system and successful practice, which effectively improves the company's quality risk prevention and control capabilities, and builds a solid foundation for promoting the high -quality development of the enterprise. Sorted machinery and equipment manufacturers.

Micro -turbine light -burning magnesium powder assigned mechanical equipment manufacturers, slag micro powder and other quantities instead of various use concrete and cement products in various uses, which can significantly improve concrete and concrete and Comprehensive performance of cement products. Standard microfilling, as a new type of mixture of high -performance concrete, has the advantages of improving various performance of concrete. The specific manifestation is: 1. It can greatly increase the strength of cement concrete and can formulate ultra -high -strong cement concrete; 2. It can effectively suppress cement in the cement The alkali aggregate reaction of concrete significantly improves the antidine antidine reaction performance of concrete concrete and improves the durability of cement concrete; Significantly reduce the amount of water secretion of cement concrete and improve the harmony of concrete; 5. It can significantly improve the density of cement concrete and improve the anti -penetration of cement concrete; 6. It can significantly reduce the hydration heat of cement concrete, suitable Volume concrete; Standard is one of the solid waste discharged during the steelmaking process. It is an oxide generated after all elements in metal furnaces. Impurities, which are specially added to adjust the nature of the slag, such as limestone, white clouds, iron ore, silica, etc.

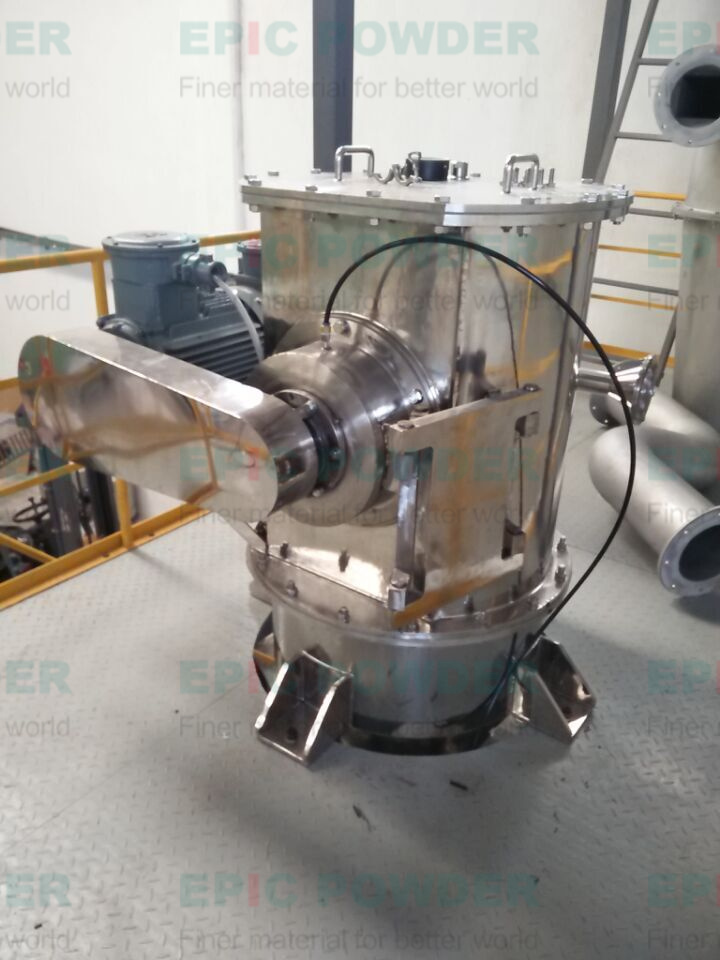

Case of Gaoling Tuki -type airflow grading machine: The customer is an Indian kaolin powder company. After inspecting many companies, no suitable one was found. In the end, the ITC600 vertical airflow grading machine provided by We Mingke Fan Machinery met the customer's needs. The hourly output of this set of equipment reaches 4T per hour.

What is the system temperature of the air flow crusher? What is the temperature of the mechanical shredder? The compressed air can produce heat expansion and absorb heat when it is released through the Rawar nozzle of the airflow crusher. The crushing process is generally not higher than 30 ° C. It is a low temperature crushing and is suitable for thermal material crushing. The material on the crushing disk during the working crusher is instantly comprehensively affected by high -speed impact, friction and shearing, and the temperature will rise rapidly. When the temperature measures are not adopted, the temperature of the crushing room is usually higher than the temperature temperature temperature than the ambient temperature. At about 30 ° C, the temperature will be higher when it encounters materials that are not easy to crush.