The process of crushing for traditional mechanical crushing is the process of crushing the material through the mechanical shear force, squeezing pressure, impact and grinding. The crushed materials need to be directly contacting the grinding body or grinding medium. Most grinding bodies are made of various metal materials, which inevitably introduce metal impurities in wear. Therefore, in the areas where lithium batteries, medicines, health products, and food require non -pollution crushing treatment, the application of mechanical pieces is greatly restricted. If you want to use mechanical pieces in industries without magnetic pollution, ceramic ultra -micro crushing machines are needed.

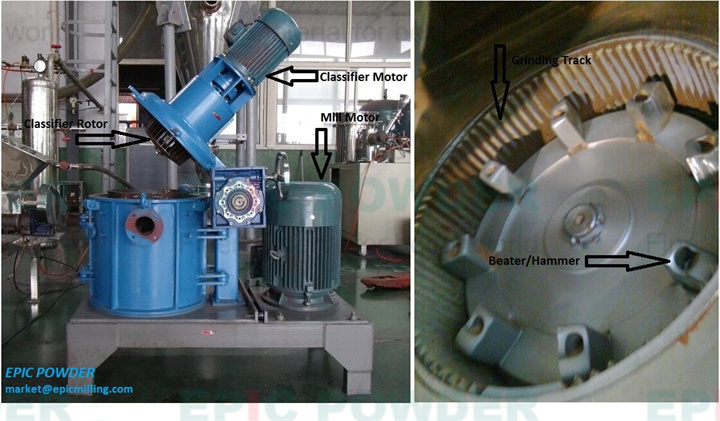

The ceramic ultra -micro crushing machine is that the part of the contact with the material during the crushing process must be the ceramic structure. In the process of studying the crushing of lithium battery materials, Qingdao Youmingke has developed and produced ceramic machinery super fine crushing machines according to customer needs. The feed size of such equipment is less than 3 mm, and the product particle size can be adjusted between 5 to 100 \u0026 mu; M. The entire equipment system has a high degree of integration, low fine powder, high revenue, good granules, strict control of large particles, and loved by battery users. The working principle of the ceramic ultra -micro crushing machine is: the material is evenly feeded in the crushing cavity through the feeding system, and at the same time, under the impact of the crushing disk, it is also affected by a centrifugal force. Various functions such as collision. The product moves to the classification area with the airflow, and the classification wheel controlled by frequency -frequency control is separated. The final product that meets the granularity requirements will be collected in the whirlwind separator and dust collector with the gas flow, and then the coarse material will be returned to the second crushing. At present, the ceramic ultra -micro crushing machine produced by Qingdao Youming scientific research has more than 20 years of application experience in the lithium battery industry. This equipment is particularly suitable for crushing materials with granular granulation of more than 5 microns and has the characteristics of efficient energy saving. With the explosive growth of the lithium battery new energy industry in recent years, the equipment will become a powerful supplement to the application of lithium battery materials such as airflow crushing equipment and sand mill. Customers can choose to be more economical according to the requirements of crushing and processing granularity of their own materials to make more economical requirements. Practical crushing process and equipment. Of course, in the crushing processing of non -magnetic pollution pollution in medicine, health products, food, and chemicals, ceramic ultra -micro crushing machines are also a very good choice.