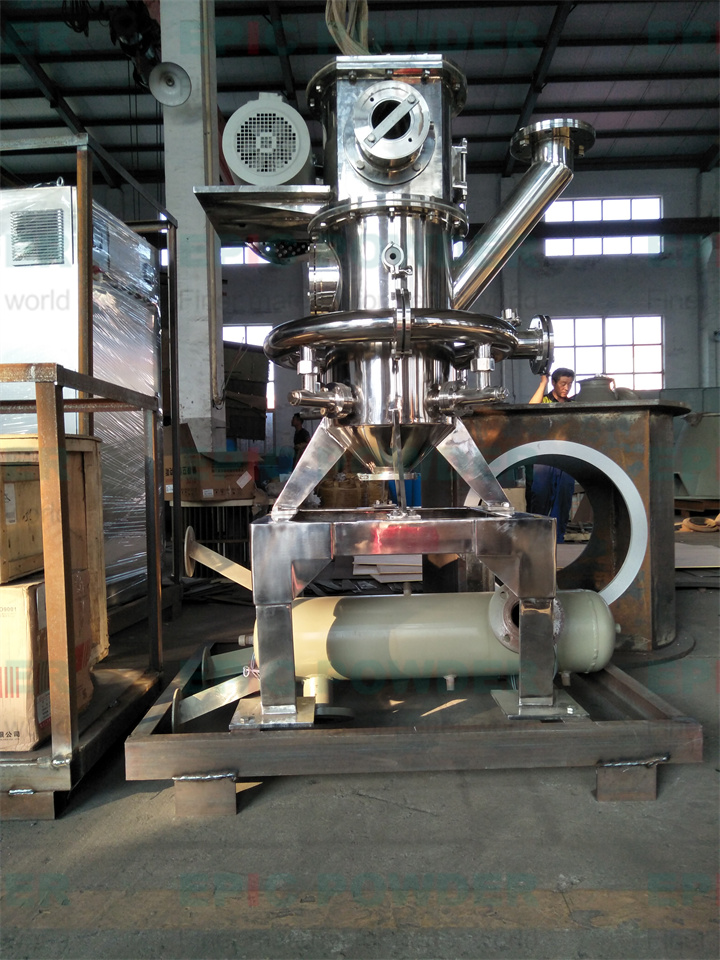

As an advocate of energy conservation and environmental protection technology, Shandong Youmingke Fan Machinery is entering a new era in product development, corporate culture, and contribution to global society. In order to achieve the ultimate goal of Shandong Youmingke Fan Machinery Machinery, Shandong Youmingke Fan Machinery has established a close cooperative relationship with customers. While Shandong Youmingke Fan Machinery Sales Network covers the country while covering the country, it also sells for many countries and regions in the world. Based on industry trend changes and channel changes, Shandong Youmingke Fan Machinery divides sales operations into three major pieces, namely: operations: operations Business channels, e -commerce and traditional channels are operated in parallel. As a new entry point for enterprises, e -commerce uses different sales strategies to support it. There are many types of mechanical pieces of Youmingke Fan Machinery Machinery, such as: MJW-L type, MJW-A, MJW-W, MJL-W, TSM soda-specific type, MJL-P needle disc type type Mechanical crusher, MZ vibration crusher, RTM vortex crusher, MJL-F hammer mechanical crusher, MRM-G series, MRM-C series and other different uses, different particle size, suitable for mechanical crushing of different materials crushing machine. There are also many application industries: battery materials, fine chemicals, metallurgical powder, medicine, non -metal mine, environmentally friendly desulfurization, high -tech materials, food/cosmetics/health products, building materials and solid waste. Here are a material introduction that we have already done experiments: 1500 mesh no water citric acid ultra -fine grinding equipment calcium carbonate is white solid, odorless and odorless. There are two forms of fixed shape and crystallization. The crystal type can be divided into a trapezine crystal and a six -way crystal system, which is column or diamond -shaped. The relative density is 2.93.825 ~ 896.6 ℃. It is decomposed into calcium oxide and carbon dioxide at about 825 ° C. The melting point is 1339 ° C, and the melting point at 10.7MPa is 1289 ° C. It is difficult to solve water and alcohol. React with dilute acid, at the same time, release carbon dioxide at the same time, showing a heat -reacting reaction. It is also soluble in ammonium chloride solution. Almost insoluble in water. You Mingke Machinery and Equipment sells more than 100 countries, and customers are spread at home and abroad. So far, more than 3,000 customers have cooperated. At present, there are several customers during the experiment and negotiation stage. Multi -customers understand You Mingke's strength and service capabilities. Cases of Youming Ke Bean Meal Mechanical milling machine: The customer is a company in the Netherlands. Van Zutven in the Netherlands, the company needs to crush the soybean meal (after the oil is squeezed). After inspecting European equipment manufacturers, in terms of comprehensive, it is still our Own Fan Fan Machinery equipment. In terms of performance, it is a better choice in terms of cost -effectiveness. Through materials, the company chose our company's MJW1250-W mechanical grinding crusher. For soybean meal crushing equipment, customers and friends are concerned about the factory quotation. As a large company manufacturing company, Qingdao Youmingke has always worked hard to provide customers with greater value.For the important information of the selected type, the pre -sale service session, Youmingke has 24 hours of online customer service to answer questions for you at any time, provides ideal soybean meal pieces production line solutions, and provides factory quotations based on this to escort the soybean meal crushing project. Professional installation and debugging to ensure smooth acceptance: Youmingke installation engineer will guide the equipment installation and debugging throughout the process until the entire production line is successfully reached the standard installation preparation stage: see the components required for confirmation of order forms and counting equipment. The drawing of the drawing is measured, geometric dimensions, etc. are measured; equipment installation phase: conduct on -site installation and planning according to the design drawing, and gradually start installation of equipment and related supporting facilities; the equipment trial operation phase: further check the equipment and perform debugging and maintenance before use to ensure the operation of the equipment operation The characteristics meet the needs of production; the equipment acceptance stage: Youmingke is responsible for training the relevant personnel. When all the project indicators of the production line meet the design standards, you will issue a qualified letter of acceptance, and 1500 mesh -free citric acid ultra -fine grinding equipment.