Under the strong advocacy of the country, \u0026 ldquo; Green Sustainable Development \u0026 RDQUO; It is the main direction of the development of major enterprises. While practicing intelligent manufacturing, it has been fully implemented in green manufacturing, which has long been the top priority of the development of Youmingke powder machinery. You Mingke Pink Machinery Practice the concept of green manufacturing, and fully builds enterprises into a model for the transformation and upgrading of traditional manufacturing.

Kaolin process process starts from crushing. At present, there are three main crushing methods. First, mechanical crushing, the crushing fine range is 300 \u0026 mdash; about 1000 meters. Second, the airflow is crushed, the crushing fine range is about 5000 mesh, because the crushed fine powder contains other mineral composition and impurities. Third, high pressure extrusion method. Therefore, different crushing methods for different purity requirements must be used to ensure its purity. Different industries need different composition of kaolin, so the level and classification of kaolin is also different. In the wet selection process, the raw ore is first made into mud, so that the minerals are unbuttoned into particles in the water, and they are separated from quartz, Changshi, and Yunmu. , Mineral impurities such as yellow iron ore, of course, can also achieve the effects we need by adding some dispersion.

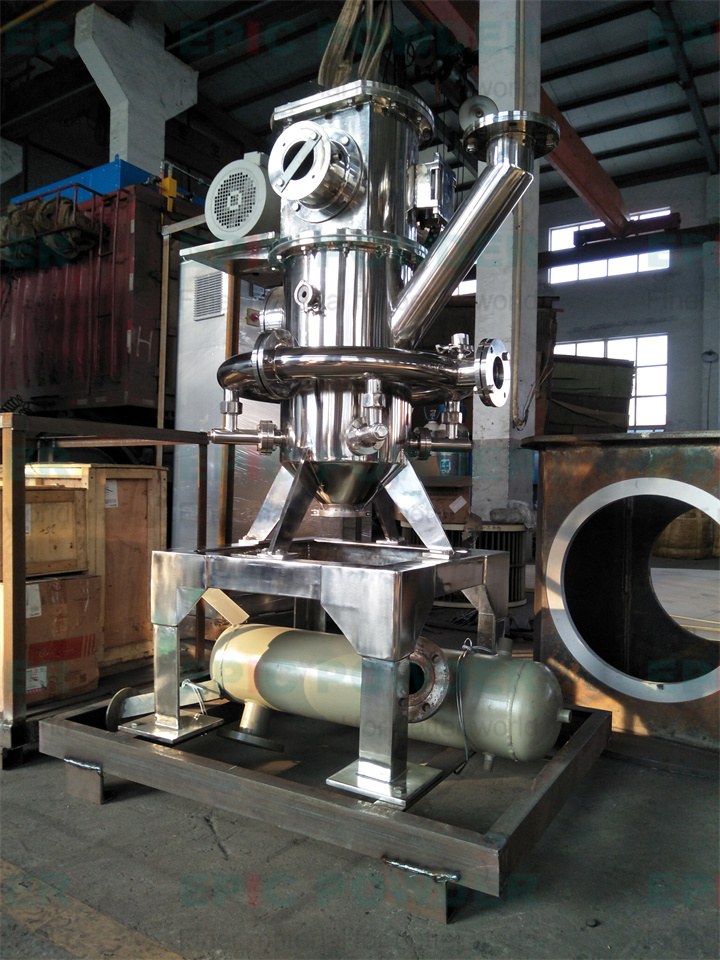

Cases of Jiying Powder Model: Jiangsu New Materials Co., Ltd. is a high -tech enterprise engaged in electronic -grade silicon micro -powder production and research and development in China. The company has four factories that manufacture silicon microflower, with an annual producing crystalline silicon microfan, melting silicon microfan, surface treatment of silicon microfan, spherical silicon microfan, and ultra -fine silicon micro powder. More than 40,000 tons of products. The company has always adhered to customer -centric, and the needs of customers quickly responded and continued to innovate, and they are committed to becoming the world's leading supplier of industrial powder materials application solutions. We continue to innovate around the needs of customers and open cooperation with partners. We are committed to provide competitive solutions and services for electronic materials, electrical insulation materials, special ceramics, precision casting, paint coatings, adhesives, functional rubber, plastic, advanced building materials, and other functional applications to create value for customers. Youmingki quartz powder grading machine HTS400 Parameter: Product Gravity: D97: 5-75UM Hours: 20-100kg Large microned pea protein granules How much does it cost

All our behavior consciousness insists on creating beautiful creation. From the perspective of the environment, it is not only committed to creating a beautiful environment for today's world, but also ahead of the world to create a beautiful environment for the future world \u0026 ldquo; green development, environmental protection priority \u0026 rdquo; is the only law of Youmingke's operations, \u0026 ldquo; Create eternal green color \u0026 rdquo; It is the eternal pursuit of Youmingke. How much is the classification process of large -scale micron protein particles.