In addition, most of the fruit and vegetable skin and nuclear are containing specific nutritional ingredients, which can be directly transformed into food raw materials through the laboratory air flow crusher. For example, the citrus peel core contains rich carbohydrates, minerals, bioflavonoids and other nutrients, and has high medicinal value.

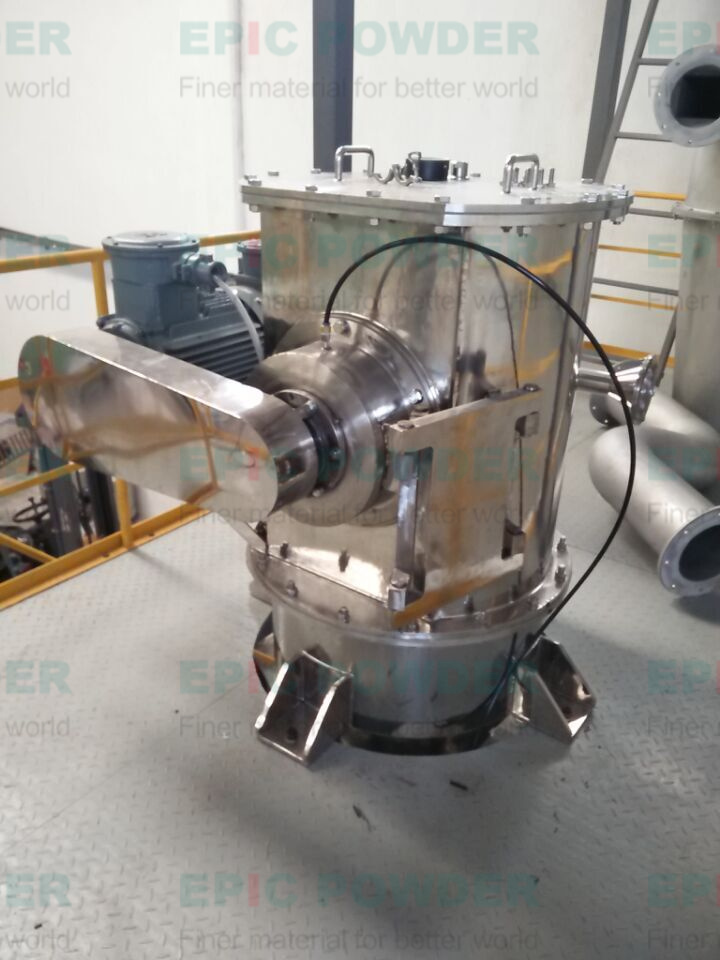

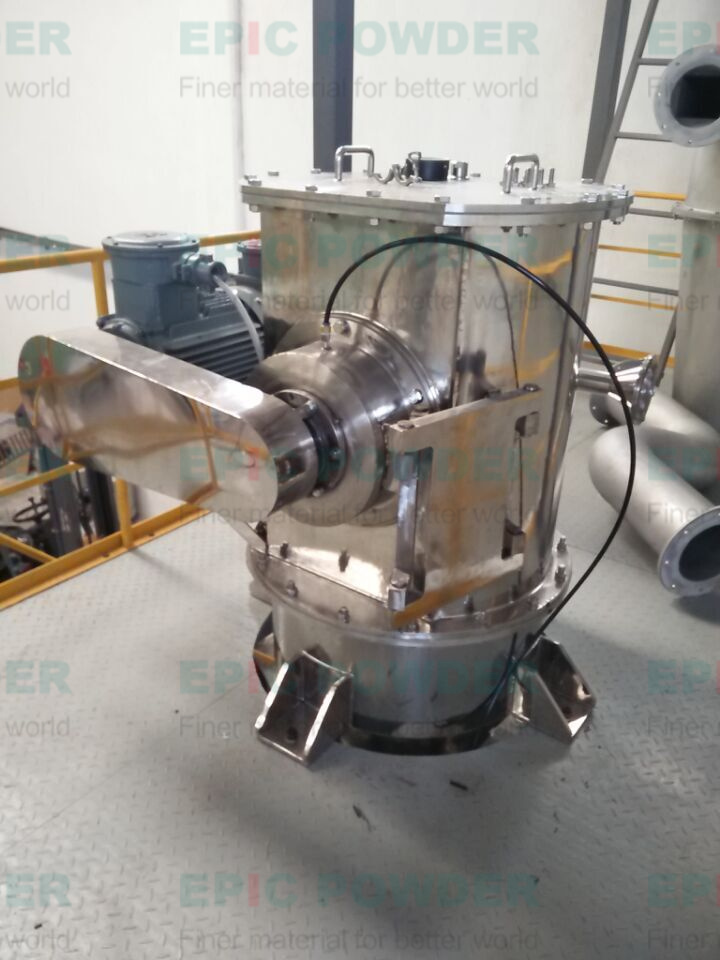

Small laboratory laboratory air flow crushing machine This machine is \u0026 ldquo; gmp \u0026 ldquo; standard design. Materials, battery materials, and super fine crushing of dry powder raw materials such as polymer materials. The machine is composed of crushing hosts, whirlwind separators, pulse dust boxes and other parts. The material enters the crushing room from the feeding bucket, and it crushes the mutual impact and friction by blowing the material by high -speed airflow. The role of centrifugal force and the infiltration fan enters the whirlwind separator. Then, through the turbine, the dust enters the veins to remove the dust collector, and is recycled after filtering through the anti -static dust removal bag. The machine is based on the standard design of \u0026 ldquo; gmp \u0026 ldquo; all of the machines are made of 304 stainless steel materials. There is no dust during the crushing process Youmingke adheres to the customer -oriented, service -core, quality of life, and adheres to the tangible tangible business concept.化、限时化、标准化、增值化的服务标准,谨守全员、全流程、全天候的S530服务承诺,为客户提供包含但不限于项目咨询、可行性分析、工艺诀窍、设备交付、安装调试、 Personnel training, after -sales service, quality thousands of miles and other EPC project total bag services.