In recent years, with the implementation of environmental protection policies, air flow crusher has a high frequency of application in the market. For users, the mastery of common faults and processing methods of air fuse is particularly important. As a well -known airflow crushing machine manufacturer in China, Qingdao Youmingke Fan Machinery Machinery has established a sound after -sales service system, and promises to act immediately after receiving maintenance information. This time, the airflow crusher quickly responded to the technical problems of the air flow crushing machine of Beijing Bei Ran Green Valley, and timely and effectively completed the repair, helping users reduce economic losses.

\u0026 ldquo; slag \u0026 rdquo; full name is \u0026 ldquo; granification blast furnace slag \u0026 rdquo; In the process of iron refining at the blast furnace, in addition to iron ore and fuel (coke), in order to reduce the smelting temperature, appropriate amounts of limestone and white clouds are also added as fuse. They decompose calcium oxide, magnesium oxide, waste ore in iron ore, and ash in coke in the blast furnace, and melt the ash in coke. On the surface of the iron water, it is regularly discharged from the residue outlet, and the air or water is treated by air or water to form a granular particulate matter. This is the slag. It contains more than 95%of the vitreous and silicate calcium, calcium yellow stones, silicon ash and other minerals, which are close to cement components.

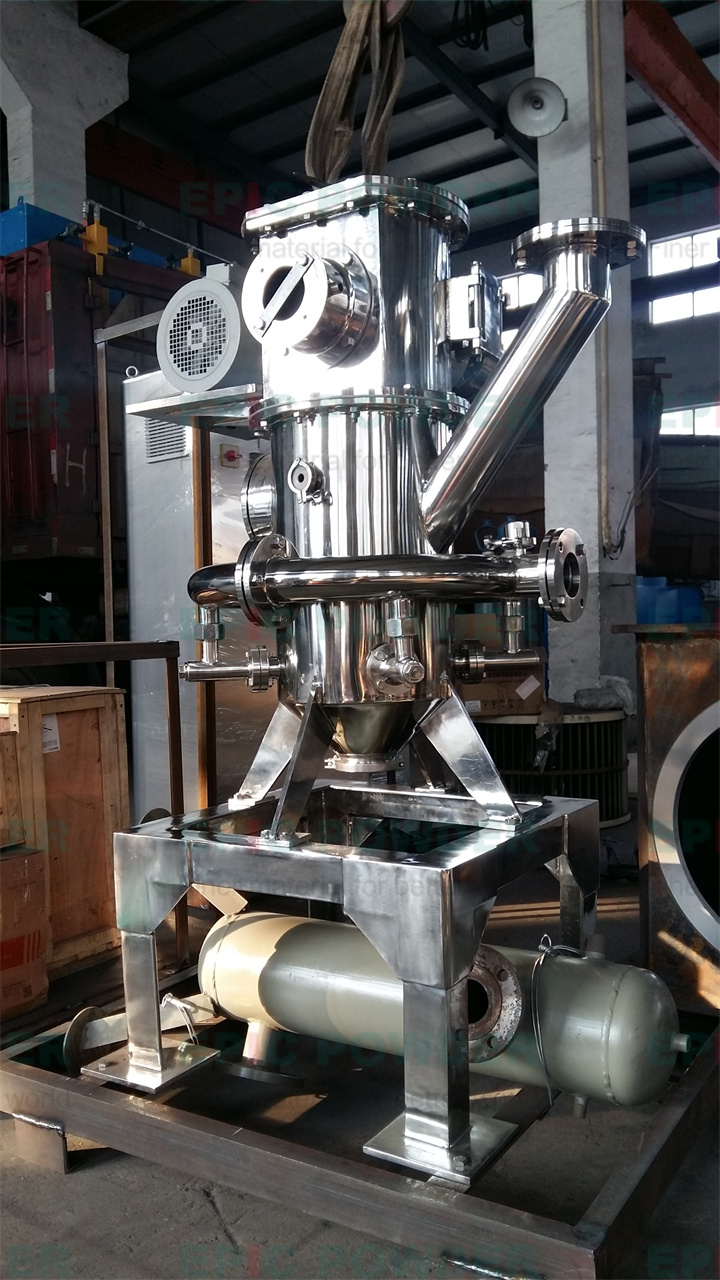

The laboratory dry method epoxy resin fine powder sorting system manufacturers, Youmingke Gaocun quartz powder grades case: Jixi County, a quartz Co., Ltd. was founded in 1987. , Wutun Highway and Anhui and Jiangxi Railway are passing by, and the transportation is extremely convenient. The company integrates mineral mining and processing. It has more than 20 million yuan in fixed assets, more than 120 employees, 30,000 tons of silicon micro -powder and quartz powder, and the production scale and market share are before domestic peers. The company has strong technical power, advanced detection instruments, perfect pre -sales, mid -sales, and after -sales service. It can provide eight series and nearly 100 silicon microfan products for different customers. While learning and drawing on advanced technologies at home and abroad, the company has continuously improved and improved product quality, and has passed IS09001: 2008 international quality management system certification. The company strives to meet customers' requirements with excellent product quality and high -quality services. You Mingke High Pure quartz powder HTS630/4 Parameter: Product Gravity: D50: 3.5um Hours: 800kg Laboratory Dry Epoxy Powder Formation System Manufacturer

Persistence global development Provide customers with high -quality products and services. In the steady global strategy advancement, the marketing network has expanded to more than 100 countries and regions in the world. Products have won widespread praise in Germany, France, Italy, Switzerland, the United States, Canada, Brazil, Turkey, Russia and other markets.