As early as at the beginning of the company's establishment, Qingdao Youmingke gradually introduced modern technology into the traditional production method of the ultra -micr -powder equipment industry to achieve mechanization, informatization and intelligence of the airflow crusher production line. The fully automated production line not only greatly improves production efficiency, but also more importantly, the processing size of the components of each airflow crusher is more accurate, and at the same time, the product quality problems caused by human factors are reduced as much as possible. Nowadays, Qingdao Youmingke has multiple automated production lines to ensure the processed airflow crusher components, and the size is absolutely uniform. The assembly between components is easily achieved, and there is no mandatory assembly.

Heavy crystal is a very important non -metallic mineral raw material with extensive industrial use. Heavy crystal stone for the filler industry: In the paint industry, the filling of heavy crystal stone powder can increase the thickness, strength and durability of the paint film. Zinc -white pigment is also used to make white paint, and it has more advantages in indoor use of lead white and magnesium white. The paint industry's heavy crystal requires sufficient fineness and high whiteness. The papermaking industry, rubber and plastic industries also use heavy crystal stones as fillers. This filler can improve the hardness, abrasion resistance and aging resistance of rubber and plastic. For rubber and papermaking, the BASO4 is generally more than 98%, and the CAO is less than 0.36%. It is not allowed to contain magnesium oxide and lead. Cement industry minerals: The use of stones and fluorite composite mineralizers in cement production has obvious effects on promoting the formation of C3S and activating C3S. The quality of the clinker has been improved. ~ 25%, the intensity of the later period increases by about 10%, and the fixture firing temperature is reduced from 1450 ° C to 1300 \u0026 plusmn; 50 ° C. When the weight of the heavy crystal is 0.8 to 1.5%, the effect is the best. In the production of white cement, after using heavy crystal and fluorite composite minerals, the firing temperature was reduced from 1500 ° C to 1400 ° C. The content of free CAO was low, and the strength and whiteness were improved. Adding an appropriate amount of heavily spar to the cement raw material with coal vermiculite as the raw material can make the intensity of cement with low saturation ratio, especially the early intensity, which is greatly improved. Low calcium, energy conservation, early strong and high -strength cement provide a beneficial way.

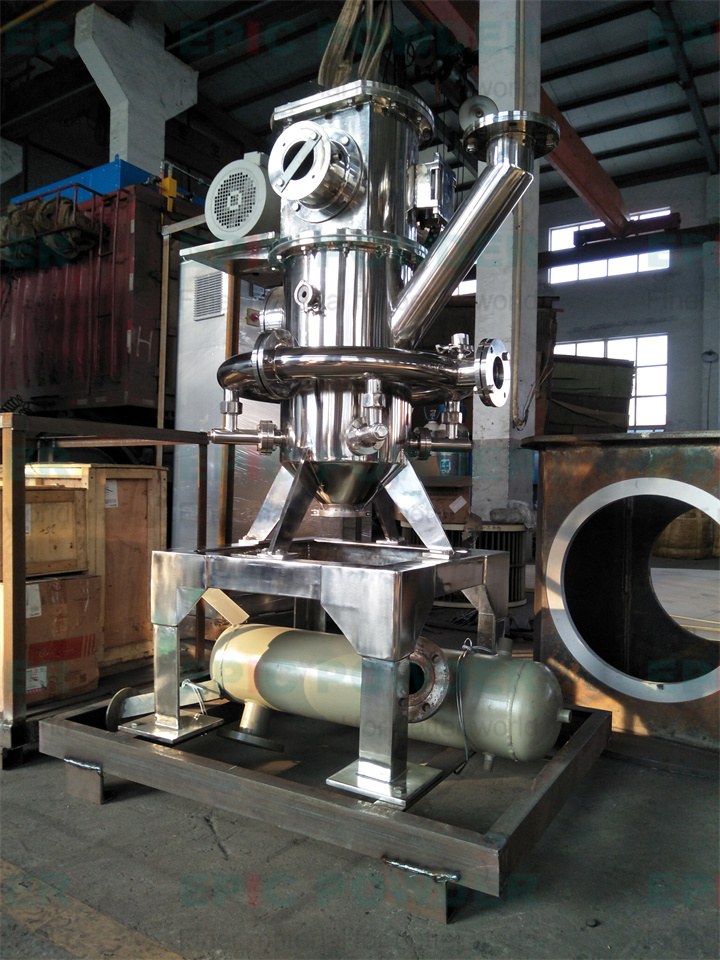

Micro -dry -drying aluminum aluminum microfilling process price, Youmingke ITC360 vertical airflow grading machine for silicine powder grading experiments: Qingdao environmental technology company due to production needs due to production needs , Need to classify siliconate ultra -micro powder, because it is not sure whether it can meet the demand, so it is expected to perform experiments. Through experiments, the ITC360 type airflow classifier of Our Our Mingke powder machine can be used. Ultra -micro powder is graded, and finally the granularity obtained by the experiment: D90: 18.3 \u0026 mu; M, output: 460kg/h feed, welcome to the major powder grading demand manufacturers, visit the factory, come to the experiment.

The price of micro -dried crickets and aluminum aluminum microfilling micro -powder, Youmingke actively responds to the country's sustainable development strategy, and the products developed can meet the crushing needs of various materials.The pollution materials and source of the key difficulties of the enterprise were dealt with more properly, and it became a treasure.It greatly reduces the pollution caused by factory production and emissions on the atmosphere and ecological environment, enables enterprises to get greater value, and also green the earth.