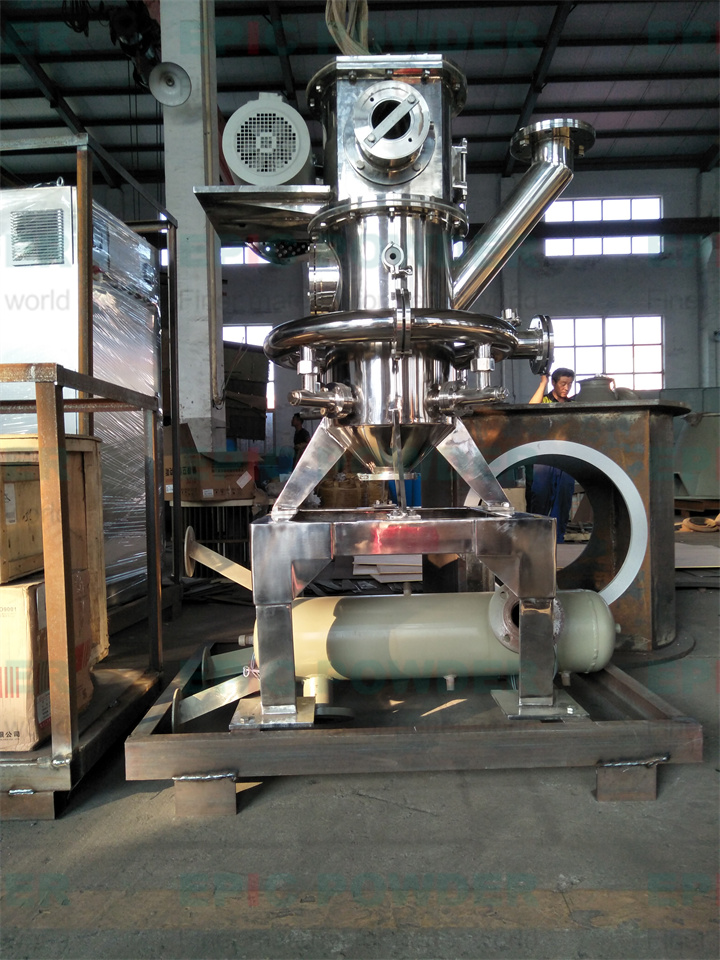

In terms of quality testing, the details of Youmingke powder machinery are particularly strict. As we all know, there are often hundreds of manufacturing processes of super -microfanten equipment. As a special equipment, the air flow crusher, any process in the production process may cause a big disaster. Therefore, Yimingke Fan Machinery has set up seven process stop points in the entire production process, which are strictly controlled by different engineers, and each other is independent and supervised with each other to find out problems and solve problems in a timely manner. Any details are unqualified and cannot enter the subordinate process. This is the quality monitoring of the whole process of Youmingke Fan Machinery for the entire process of production. There are many types of mechanical pieces of Youmingke Fan Machinery Machinery, such as: MJW-L type, MJW-A, MJW-W, MJL-W, TSM soda-specific type, MJL-P needle disc type type Mechanical crusher, MZ vibration crusher, RTM vortex crusher, MJL-F hammer mechanical crusher, MRM-G series, MRM-C series and other different uses, different particle size, suitable for mechanical crushing of different materials crushing machine. There are also many application industries: battery materials, fine chemicals, metallurgical powder, medicine, non -metal mine, environmentally friendly desulfurization, high -tech materials, food/cosmetics/health products, building materials and solid waste. Here are a material introduction that we have already done experiments: Stalks are efficient and long -term light industry, textiles and building materials raw materials, which can be partially replaced by bricks, wood and other materials, and can also effectively protect cultivated land and forest resources. The insulation, decorative and durability of straw wall boards are superior. Many developed countries have used \u0026 ldquo; straw; straw boards \u0026 rdquo; as a substitute for wooden boards and tiles, they are widely used in the construction industry. In addition, the processing of machining straw can also be used to make artificial silk and artificial cotton, produce branfamal, sugar, alcohol and kalitol, processing fiber plates, and so on. 1670 mesh ternary or cobaltate microfilling grinding equipment, Youmingke machinery equipment has sold more than 100 countries, customers are located at home and abroad, so far, more than 3,000 customers have cooperated. Several customers, randomly screen a display as a display to facilitate more customers to understand the strength and service capabilities of Youmingko, 1670 mesh triad or cobaltate microfilling equipment. 优明科白炭黑机械磨粉碎机案例:该公司主营的年产15000吨白炭黑,主要用于轮胎、制鞋业、硅橡胶行业以及饲料、农药、 Coatings, inks, paint, toothpaste and other fields are very widely used. The company is a large -scale company specializing in white charcoal and black production. It requires a super -micro crushing equipment for white carbon black products that can produce two granular black products during the production process. After inspection, the MJW510-L type mechanical grinding crusher of Our Famous Powder Machinery was finally purchased. Technical parameters of white carbon black mechanical grinding crusher: Product particle size: D50: 6.78 d90: 12.8 \u0026 mu; M Production capacity: 30kg For white charcoal and black crushing equipment, customers and friends are concerned about what is the factory quotation. As a large company manufacturing company, Qingdao Youmingke has always worked hard to provide customers with greater value. The fineness, production capacity, and installation venue of each project are important information for customized selection. Pre -sale service links, Youmingke has 24 hours online online. Customer service will always answer questions for you, provide ideal crushing machine production line solutions, and provide factory quotations based on this to escort the white charcoal black crushing project. Various white charcoal black manufacturers are welcome to consult. What is the system temperature of the airflow crusher? What is the temperature of the mechanical shredder? The compressed air can produce heat expansion and absorb heat when it is released through the Rawar nozzle of the airflow crusher. The crushing process is generally not higher than 30 ° C. It is a low temperature crushing and is suitable for thermal material crushing. The material on the crushing disk during the working crusher is instantly comprehensively affected by high -speed impact, friction and shearing, and the temperature will rise rapidly. When the temperature measures are not adopted, the temperature of the crushing room is usually higher than the temperature temperature temperature than the ambient temperature. At about 30 ° C, the temperature will be higher when it encounters materials that are not easy to crush.