In the new era, new demands are created. As economic growth gradually transformed from extensive types to intensive environmental protection, various industries are facing infinite opportunities and challenges. Among them, Yumingke powder machinery, which is a typical representative of industrial powder equipment manufacturing enterprises, is environmentally friendly powder equipment for the product of the new era \u0026 mdash; \u0026 mdash; It has its own value.

Aluminum alumina microfilling is a kind of internal tissue structure of alumina alumina after high temperature burn of 1550 ° C, from a variety of crystal types to \u0026 alpha; -a1203 phase phase phase phase phase phase The aluminum oxide powder is then treated with powder to form a white microcomio -alumina powder, that is, alumina (high -temperature aluminum oxide micro powder).特 Aluminum aluminum microfimpen is particularly applicable to irregular refractory materials such as firing refractory products and fire -resistant pouring materials, plastic, repairing materials, spraying materials, and application materials. The role.

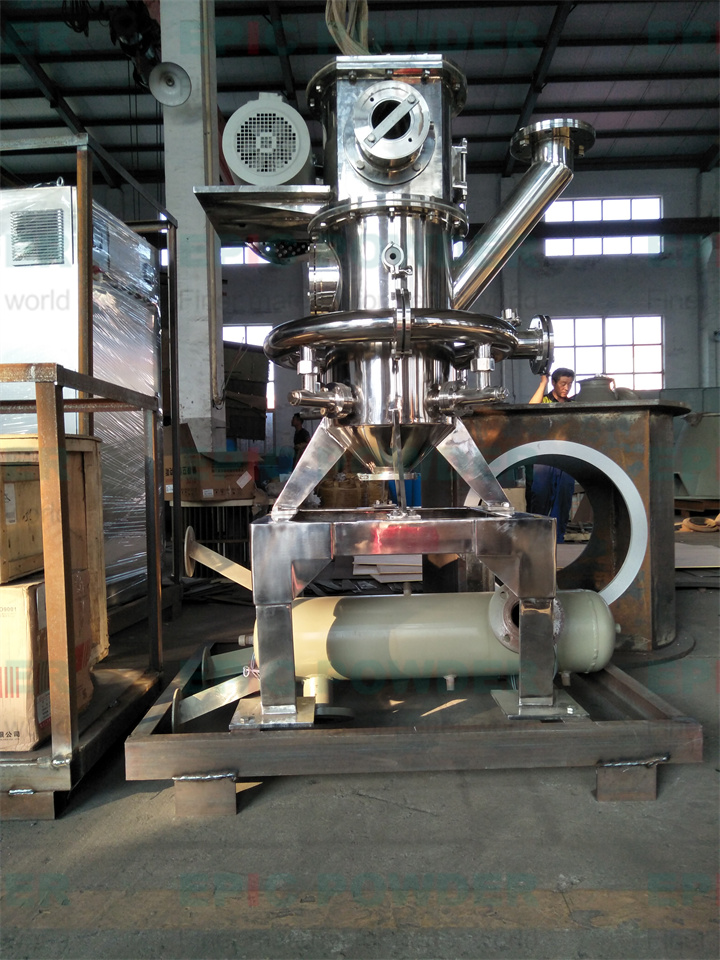

Cases of Jiying Powder in Youming Ke: Lianyungang Silicon Micro powder Co., Ltd. is a Japanese -funded enterprise with a registered capital of 2.7 million US dollars. Located in the 323 Provincial Highway Industrial Concentration Area, Shihu Township, Donghai County, Jiangsu Province, it is located in a concentrated area of \u200b\u200bhigh -quality quartz. The company was established on May 27, 2011. The main products include melting quartz sand, molten silicon microfan, soft composite silicon microfan, high -purity ultra -fine silicon microfan, active silicon microfan, crystalline silicon microfan, and spherical silicon microfim. Main uses: photovoltaic solar industries and electronic packaging materials, high -temperature refractory materials, aerospace materials, quartz glass tube, quartz ceramic rollers, and copper -covering industries. Youmingki quartz powder classifier HTS315-4 Parameter: Product Gravity: Remove 20um with fine powder hours: Sorting efficiency of 60-90% Laboratory air-streaming aluminum aluminum aluminum powder sorting system manufacturer

Excellent excellence Talent reserves: have the advantages of the envious talents in the industry, product research and development, process engineers, and project managers have been created in multiple aspects. The perennial customer live practice experience has been combined in theory and practice. The process control, the smooth advancement of science and economy, and the laboratory air -flowed aluminum alumina powder sorting system manufacturers.