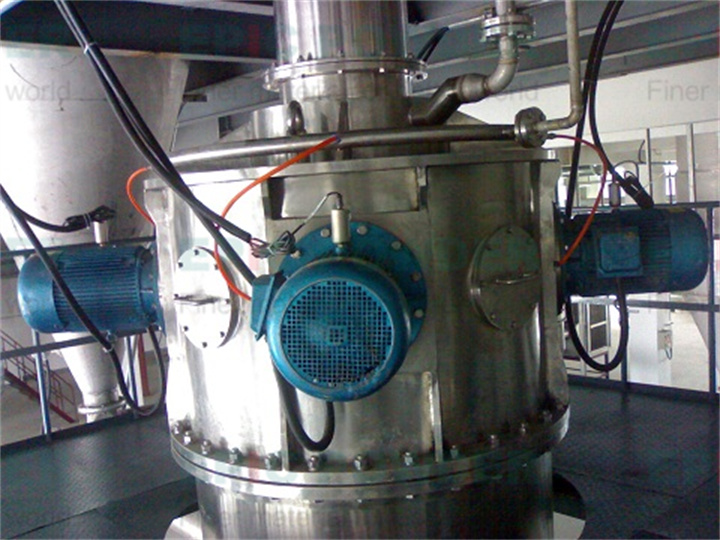

From the problem consultation to the design of the plan, Youmingke provides customers with the most professional answer and the most comprehensive solution, and assist customers to formulate construction plans to provide customers with the most professional \u0026 ldquo; Mingke has served more than 3,000 customers at home and abroad, and its sales spread to more than 100 countries and regions in Asia, Africa, Europe, the United States and Oceania. Praise, 1250 mesh cobaltate ultra -micro grinding equipment. There are many types of mechanical pieces of Youmingke Fan Machinery Machinery, such as: MJW-L type, MJW-A, MJW-W, MJL-W, TSM soda-specific type, MJL-P needle disc type type Mechanical crusher, MZ vibration crusher, RTM vortex crusher, MJL-F hammer mechanical crusher, MRM-G series, MRM-C series and other different uses, different particle size, suitable for mechanical crushing of different materials crushing machine. There are also many application industries: battery materials, fine chemicals, metallurgical powder, medicine, non -metal mine, environmentally friendly desulfurization, high -tech materials, food/cosmetics/health products, building materials and solid waste. Here are a material introduction that we have already done experiments: Silicate minerals are a type of oxide -containing minerals composed of metal cedies and silicon root. It is very widely distributed in nature and is the main mineral that constitutes the crust and the upper mantle. It is estimated that it accounts for more than 90%of the entire crust; the content in stone meteorites and moon rocks is also very rich. There are about 800 ore species known, accounting for about 1/4 of the total number of mineral species. Many silicate minerals such as asbestos, Yunmu, talc, kaolin stone, monatopolite, and zigza are important non -metallic mineral raw materials and materials. You Mingke Machinery and Equipment sells more than 100 countries, and customers are spread at home and abroad. So far, more than 3,000 customers have cooperated. At present, there are several customers during the experiment and negotiation stage. Multi -customers understand You Mingke's strength and service capabilities. Cases of Yumingke's precipitated sulfuric acid scallion mechanical crushing machine: A chemical raw material company in Shenzhen needs multiple large outputs, low -grained sedimentation sulfate crushing production lines. Our Youmingke Fan Machinery Co., Ltd. is a large enterprise in the powder equipment industry, and our company's equipment has implemented customized services. Non -standard customization is used to meet different needs of different companies. In response to the company's needs, our company customized the production of five MJW1250-L types, large-scale mechanical sedimentation sulfate sulfate crusher production lines to meet the customer's production needs. Technical parameters of precipitated sulfuric acid 钡 mechanical crushing machine: Products granularity: D50: 0.8-5 \u0026 mu; M Production capacity: 4.5 \u0026 plusmn; 10%/t For precipitated sulfuric acid sulfuric acid说 For the crushing equipment, customers and friends are concerned about the factory quotation. As a large company manufacturing company, Qingdao Youmingke has been working hardProvide customers with greater value. The fineness, production capacity, and installation venue of each project are important information of customized selection. Pre -sale service links, Youmingke has 24 hours of online customer service to answer questions for you at any time and provide ideal pieces.The production line solution, and the factory quotation is provided according to this to escort the crushing items for the sedimentation sulfate. 1250 mesh cobaltate ultra -micro -grinding equipment powder processing production area is clean, and the production area strictly controls the pollution of microorganisms to work objects, which meets the corresponding \u0026 ldquo; static \u0026 rdquo;Controlled environment.Without metal pollution, the agency processing equipment uses different lining materials according to the needs of the material. From the incoming side to the discharge end of the discharge end, the increase in metal foreign matter is controlled to the PPM level.Standards for zero pollution of processing materials.