The crusher selected by the airflow classifier in the production process requires the granularity of the product to be distributed within a certain range. In fact, the granularity distribution of the product produced by the crusher is wider than the required particle size range. fulfil requirements. Therefore, in the process of crushing, the grading is one of the important links that improve the efficiency of ultra -fine crushing and produce fine powder products that meet the fine powder and their levels.

First, in the process of ultra -fine crushing, as the crushing time is prolonged, the grain size gradually decreases; at the same time Increasing; therefore, the trend of micro -granulum mutual agglomeration has gradually increased. After a certain period of time, the ultra -fine crushing is in the dynamic balance process of crushing and reunion, that is, to achieve the so -called crushing limit. In this state, even if the crushing time is extended, it is difficult to reduce the particle size, and sometimes even the surface of the product becomes thicker. In order to improve the crushing efficiency and reduce energy consumption, in addition to improving the crushing machine and adding abrasives (or dispersion) in crushing, the important point is to timely distribute qualified fine -grained products to avoid qualified fine -grained granular levels Materials have powder grinding in the mill. To this end, it is necessary to set up effective fine grading equipment in the ultra -fine crushing process.

Second, the related application areas of ultra -fine powder, such as microelectronics, high ceramics, high abrasives, paper fillers and coatings, plastic and rubber fillers, coatings or fillers, ink powder and other pairs of ultra -fine powder There are certain requirements for granularity distribution or grade distribution, and some requirements are relatively strict. Only fine grading of ultra -fine powder subsequent products can be met. Therefore, there are two main functions of classifiers: one is to improve the crushing efficiency and reduce the reunion of fine particles in crushing; the other is to ensure the fineness and particle size distribution of the product.

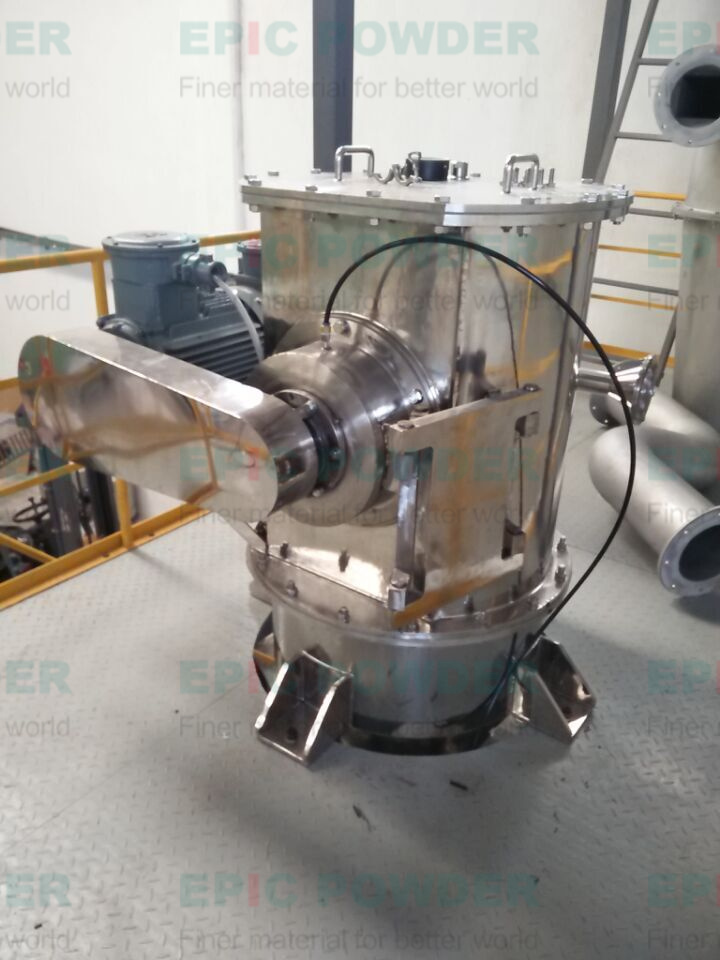

Therefore, the so -called hierarchy is the operation process of sorting the crushed products according to the size of the production process according to the requirements of the production process. There are two types of grades: sieving with sieves and grading in fluids. Sieved sieving represents the main products such as straight line sieve and round vibration sieve. The airflow screening represents the product with a gravity classifier, a thick grade machine, a centrifugal grading machine (also known as a centrifugal powder selection machine), a whirlwind classifier, O-SEPA classifier, jet vortex classifier, forced vortex flow Grade machine.