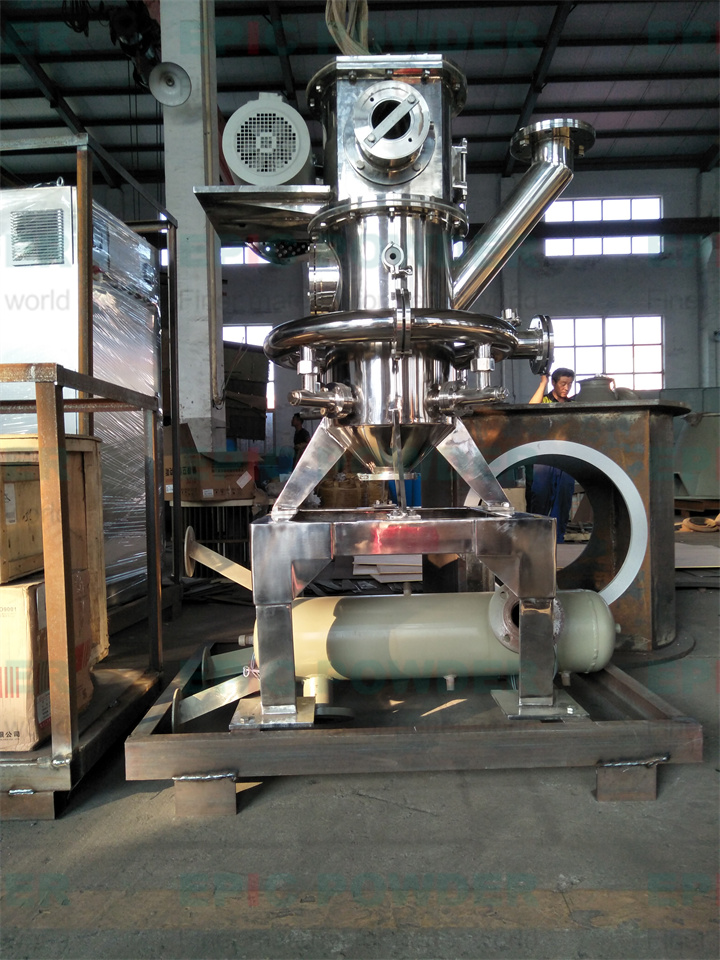

With the large number of airflow crusher, many manufacturers and other manufacturers are considering the question of whether low melting points and thermality are reliable. The advantages brought by the crusher to everyone are obvious to everyone, which has indeed greatly improved production efficiency. The airflow crusher adds a feeding mouth to the feeder because the electromagnetic vibration machine is added to the material, and the high -speed dry air -flow belt zoom collides with each other. There are high -speed dry air flow band zooms that collide with each other to make them crushed. Some of the more delicate powder particles that are qualified are driven by the heart gas flow and then collected through the cloth bag. Some particles are relatively large. Re -crushing and continuing the powder process with the high -speed movement of logistics.

In order to facilitate some materials to crush, what we use is a built -in hierarchical device, so that when we use The fineness distribution of our material products is very uniform, the surface of the particles is smooth, the shape of the shape, high purity, high activity, and good decentralization.

This one is very convenient when disassembling and installation. When we clean it, there is no dead ends in the inner wall. Clean up. We can also use some low -melting points and thermal materials and biological activity products. The airflow crusher uses compressed air for work. It will not produce very large calories when compressed, so we use it very reliable.