The product technology of the airflow crusher has been widely valued by the industry. The grinding mechanism of air flow crusher is mainly used to determine its extensive application range, high metropolitania, and typical materials: ultra -hard hard diamond, silicon carbide, metal powder, high purity requirements: ceramic paint, medicine, biochemistry, medicine. The airflow crusher can transform ordinary gas sources from the gas source to nitrogen, carbon dioxide and other inert gas. It is an inert gas protection device that is suitable for flammable and explosive, crushing, grading, and processing of oxidized materials.

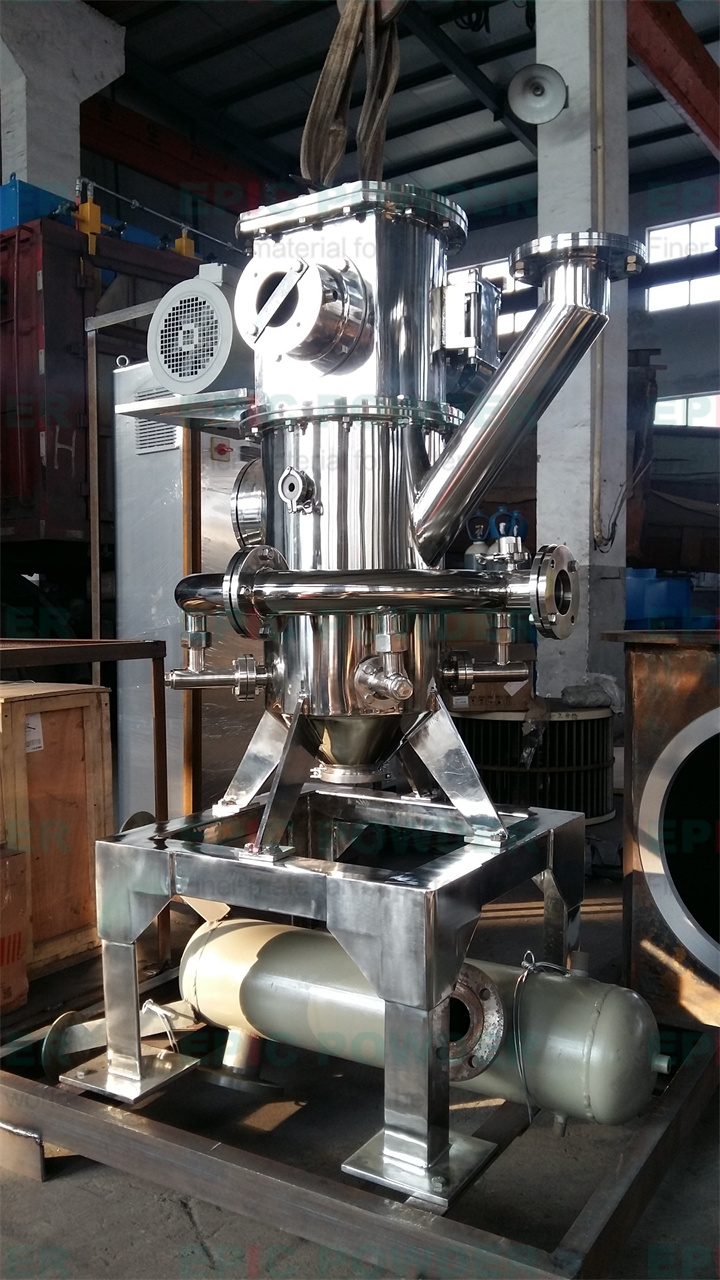

What is the design structure of the air flow crusher? Under the action of high -speed rotating impeller, the gas pressure flowing through the impeller increases, and the high -pressure airflow rotates from the leaves, and the fine granular ring is ejected. Due to the design of the blades of the rotating leaf, the section of the entrance is large and the exit section area is small. Therefore, the air flow pressure at the exit decreases and the speed increases. The rotation flow is conducive to classification. The crushing point adjustment mechanism sets three adjustment rods and uses the chain to maintain its synchronous movement. When the adjustment rod moves up, the fine powder increases; when the adjustment rod moves down, the fine powder decreases. The crushing points can be continuously adjusted, and the particle size of the airflow crusher with good performance can be regulated. The particle size of the crushing weight products can reach D97 ≤ 3≤150 microns, which is suitable for fine crushing of dry micron products. The setting of the control ring is to ensure that a suitable cross -section is formed between the control ring and the refined granular ring to control the stability of the air flow flow. The residual air outlet inevitably introduces excessive gases from dry materials. The temperature of the crushing room is high, and the air will swell. Therefore, a residual air outlet is designed to maintain the stability and balance of crushing indoor airflow.

The working principle of the airflow crusher equipment is introduced below: L, the crushing equipment uses the wall effect of the shooting to effectively combine the inertia, centrifugal force and suspension, and designed it as a novel ultra -fine powder shooting flow. grinder. The crusher reaches, high accuracy, and can smash the functions of three levels of products: thick, medium and fine powder at the same time. 2. There is no motion component of the firing crusher, and only high -pressure air is required for working medium. It is reliable and convenient for maintenance and maintenance for crushing machine hosts. The adjustment of crushing granularity is also very convenient. Just adjust the flow meter and several gate valves arranged on the machine to easily adjust the crushing particle size.

Case sharing of Yinghe quartz powder air flow crushing machine: The main products of a silicon micro powder company include melting quartz sand, molten silicon micr powder, soft composite silicon microfan, high -pure ultra -fine silicon microfan, active silicon powder, crystalline silicon microfan,, crystalline silicon microfan Silicon -shaped microfimm and other specifications are complete. Main uses: photovoltaic solar industries and electronic packaging materials, high -temperature refractory materials, aerospace materials, quartz glass tube, quartz ceramic rollers, and copper -covering industries. Case parameter: product granularity: Remove 20um with fine powder hours: 60-90%of the sorting efficiency

Electric maintenance measures for air flow crusher Whether the firmware is tight. 3. Check whether the transmission belt is installed correctly and the situation is good.The belt damage should be replaced in time. When the belt or tank wheel has oil pollution, the applied cloth is cleaned in time.4. Check whether the protective device of the pieces is good. If the protective device is found abnormal, it should be excluded in time.5. Check whether there are materials or other debris in the damaged cavity. If you sometimes be cleaned in time.6. Check whether the top head or the top rod is returned, and adjust whether the pad is installed correctly and tightly.

Shandong Youmingke Powder Machinery is a domestic ultra -micro crushing equipment and powder solution provider.Introduce foreign advanced crusher technology, independently develop, and has a complete ultra -fine crushing process process and production line.The airflow crusher, airflow classifier, laboratory crushing equipment, powder modified machine, etc. The quality can be comparable to imported crusher to meet the crushing, classification, and modification needs of different industries.

Qingdao Youmingke Powder Machinery is a scientific and technological enterprise that produces various airflow crushing machines, airflow grinding, disk airflow crusher, and discluder airflow crusher.