The airflow crusher is a very common and commonly used crusher. It has a wide range of applications and involves many industries.

The airflow crusher is convenient and convenient for maintenance, and has a high grinding speed in the same product. At the same time, low energy consumption is the lowest of similar products. Products with the same particle size do not have the function of granularity and granular dispersal. The combustible, explosive, and oxidized materials can be used as a medium to achieve closed crushing and inertia. The loss of the use of sex gas cycles is very low. Negative pressure production can effectively reduce dust pollution, improve the working environment, compact structure, and use seamless welding technology inside to facilitate mechanical maintenance and mechanical cleaning. Because the high -pressure gas is sprayed from the nozzle, the airflow causes the animal material to collide, shear and friction between the materials, thereby achieving the broken effect. Due to the high -speed rotation of gas and animal materials, a great centrifugal force is generated. Under the influence of the great centrifugal force, the thick particles were sent to the crushing room for multiple crushing, and fine powder was discharged from the central exit.

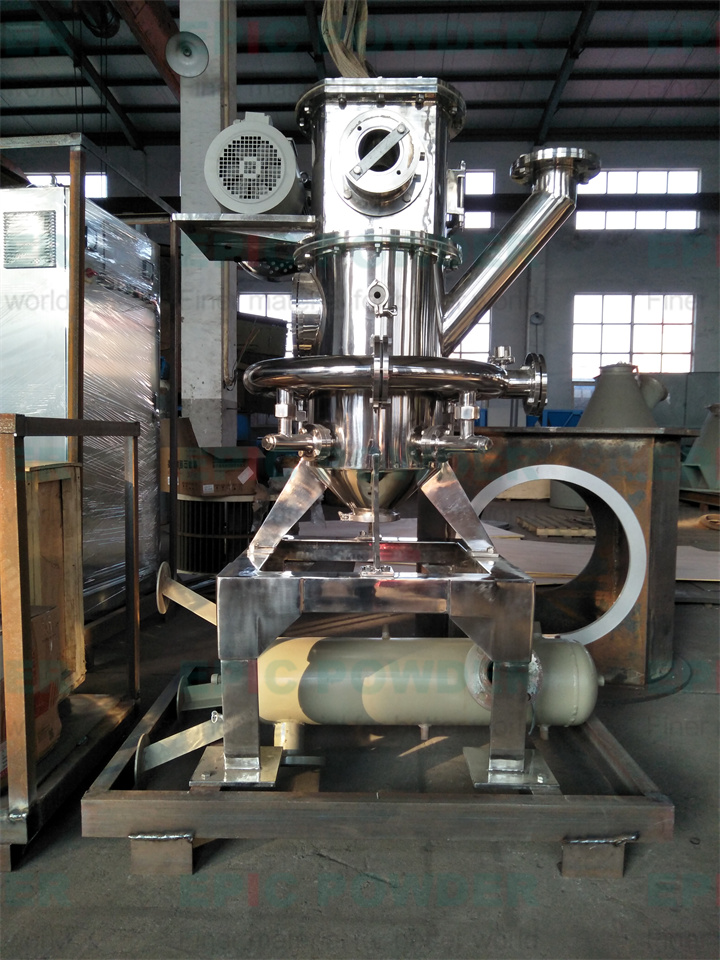

The working principle of the airflow crusher consists of a crusher, a whirlwind separator, a dust collector, and an induction machine. Under the effect of pumping power in the crusher fan, the under -end inlet of the air crusher moves upward to the crushed area, and the thick and thin material is separated from the strong heartpower generated by the high -speed rotation of the crushing turbine. Enter the whirlwind separator or dust collector by crushing wheels, collect fine particles that meet the particle size requirements, and collect coarse particles. The speed of the thin particles of the clip disappeared and dropped along the two air outlets of the cylinder wall. The thick particles and fine particles are separated through the strong purification effect of the two winds. The fine particles rose to twice the product zone, and the thick particles dropped to the discharge port.

You Mingke Composite Materials, Molten Silicon Micro Powder Flow Elix Character Case Sharing: A silicon micro powder company is a manufacturer of silicon micro -powder production earlier. The front, mid -sales and after -sales service can provide different mid -high -end customers with ten major products such as high -quality crystalline silicon micro powder, high -pure melting silicon microfan, and high -white ultra -fine silicon micro powder. The company is committed to providing favorable solutions and services in other functional applications such as electronic materials and special ceramics. The company continues to innovate around the needs of customers. It has always adhered to customer -centric, quickly responding to customer needs, tailor -made suitable high -quality products for customers. Hours output: 300kg

The problem of dust leakage in the air flow crusher can be handled from the following aspects 1. Install filtering dust removal equipment. For the dust generated by high -temperature crusher, foam dust removal, wetter dust removal, ultrasonic atomization technology, composite filter bag dust removal, folding dust collection bag, wide -spacing electric dust collector dust collector. Users can also consider the overall performance of dust removal, so a combination of dust removal should be adopted. 2. Due to the slight leakage of dust during the production process, the dust will emerge and cause pollution to the working area. Therefore, users need to ensure the sealing of the pneumatic grinding machine. 3. Add designPrepare the humidity of the operating area, strengthen ventilation, and store fire -fighting equipment, which can avoid a large amount of dust inhaling the harm caused by the human body.4. Production enterprises shall be equipped with corresponding protective supplies for the air compressor operators in accordance with regulations, and the operator shall also correctly wear protective supplies in accordance with regulations.5. Do the maintenance and management of existing dustproof equipment to ensure its normal operation and play a role in dustproof.The maintenance management of high -temperature crusher seems simple, and the actual operation requires a good attitude and habit.

From the problem consultation to the design of the plan, Youmingke provides customers with the most professional answers and the most comprehensive solutions, and assists customers to formulate a construction plan.The engineer participated in the entire process of equipment installation, commissioning, equipment use training, and regular inspection and return visits. Each part of them are intertwined to provide customers with the most professional \"nanny -level\" private customization services.

Ultra -fine -grading machines, precision grading machines such as Youmingke Technology Co., Ltd. can effectively ensure the purity and accuracy of classified products. If you need to buy related equipment, please contact us at any time.Essence